Focused on the Goal

GH India has come a long way from its humble roots. From working out of a rented shed to owning a state-of-the-art facility sprawled over two acre, the company’s journey has been a tour-de-force in every possible sense of that phrase.

GH Group, one of the largest induction companies in the world with headquarters in Spain, has been in India as a joint venture partner of GH India for the past 23 years.

GH India, commencing its operations in 1998 from a rented shed in Ambattur Industrial Estate, Chennai, moved on to its own 20,000 sq ft built-up area in Thirumudivakkam Industrial Estate in 2000. In 2013, the company moved to its state-of-the-art facility spread over two acre.

The company started with a net worth of `5 million, 15 employees, and a turnover of `25 million in its first financial year of nine months and is now comfortably placed with a net worth of `301.50 million, 140 employees, and a turnover in the range of `400-500 million per annum.

“We take pride in offering superior European technology, fast and efficient services, and excellent process technology support with Indian flexibility and pricing. We have to our credit more than 4,000 installations worldwide. GH India has a complete know-how and access to the latest technology of the Group,” shares RV Chari, Managing Director, GH Induction India Pvt Ltd, with evident pride.

Catering to an array of industries

Catering to an array of industries

GH India is one of India’s leading players in the Induction Heating machine-building industry. The company offers complete Induction hardening solutions and manufactures Standard Vertical and Horizontal machines, including Special Purpose Machines suitable to the customer’s layout and productivity.

Induction heating finds extensive application in various industries. Providing an appropriate solution for an induction heating application requires sound knowledge of and experience in several disciplines of engineering. GH India designs and manufactures a broad range of highly engineered world-class Induction Heating capital equipment for the hardening of components used in a variety of industries such as Automobile, Steel, Railways, and Defense, among others.

GH India has developed a highly efficient generator that reduces energy consumption by 5 percent to cater to the Pipe & Tubing industry.

Some of the popular applications are: Heat-treating (surface hardening, tempering, annealing); Mass heating for forging, extrusion, upsetting; High-frequency induction welding for tube mills; Seam annealing for tube mills; Brazing for tools, cladding diffuser bottoms for cookware, motor end rings, transformer conductors; Shrink fitting; Vacuum sintering, annealing, levitation melting; and ‘plug-quenching’ of critical parts to limit the distortion.

Ninety percent of GH India’s turnover is attributed to the Automobile sector, followed by the Nuclear Power Sector, Renewable Energy Sector, etc.

Ensuring customer satisfaction

To ensure meeting the customer’s ever-changing demands, Chari explains that it’s essential to keep tabs on the market, which the company does by participating in trade events. “Our Sales and Technical Team participates in the exhibitions conducted by prestigious organizations like IMTMA, ACMA, etc. These events are eye-openers; they keep us abreast of developments, competitors, and new ideas, and they help us with customer interaction and goodwill creation. These platforms also aid in showcasing to the world the developments made in GH India,” explains Chari.

Periodically, training sessions are conducted by the suppliers on their highly specialized products, wherein the engineers from GH India are apprised of the latest developments in them.

Visits are arranged to customer places to interact with them. This exercise provides a wealth of information to GH India as the Sales & Service Team gets to know the needs and requirements of the customer first-hand. At the same time, difficulties experienced by the customer with their existing machines provide the basic data required for the Engineering & Application Team to work upon.

Shopfloor of GH Induction India Plant

Dearth of skilled personnel

Large corporations and SMEs are both equally inflicted with the issue of a dearth of skilled personnel. Chari shares how GH India tackles this issue in its capacity, “GH India, operating in the niche field of manufacturing customized induction heating machines, requires not only a skilled but also a well-trained workforce. For us to train our personnel, we first need to identify their qualifications, attitude, and aptitude.”

The company recruits freshers from Polytechnic Colleges, Industrial Training Institutes (ITI), and Engineering Colleges. It then gives them on-the-job training in assembly, wiring, and trials to make them understand the whole process. “It’s the most cost-effective and simple method of training your employees under expert supervision, and the newest employees are put to work straight away,” he adds. GH India tries to maintain a small buffer strength to supplement in the case of emergencies or exigencies.

The passionate team behind the success

The inspiring force behind GH India is its Promoter Director & Vice Chairman – VR Chari, a doyen in the induction field since 1964, who has had wide exposure to various industrial applications and the ability to find appropriate solutions to satisfy customer needs by adopting an out-of-the-box approach.

“Eighty percent of the managers (star members) who form the Core Team are involved in the various aspects of machine building. They have been with GH India for more than 15 years, and some of them who started as trainees at the time of its inception have grown to head various departments. This winning team is well-equipped to meet any untoward challenges that may arise at any time,” Chari shares.

GH India implements the ‘Gurukul’ system of learning for its employees. Fresh recruits work with the team leader from the problem definition stage to the development of the solution. The managers are involved right from machine and software trials to the discussions with the Control Team and review meetings with customers.

“Over the years, the sustained efforts put in by the Directors, Star Members, and all the other employees have contributed to GH India’s creating a name for itself as a dependable and versatile solution provider in the induction field,” he adds.

GH India outsources its requirements to MSMEs and concentrates only on wiring, assembly, operating software, and technical know-how required for the hi-tech niche machine building.

GH India and automation

SMEs are often reluctant to embrace automation. Chari tells us how the company has leveraged automation for its growth.

“Automation comes into effect whenever machines and computers are used for repetitive manual activities. GH India, being in the machine-building industry where each machine is unique due to customization, the scope of repetitive activities that can be automated is relatively less,” he explains.

“Extensive usage of software solutions and simulation packages such as Solidworks, Eplan, Finite Element Analysis, and extensive CNC/PLC software is part and parcel of the entire machine building process,” he adds.

GH India outsources its requirements to MSMEs and concentrates only on wiring, assembly, operating software, and technical know-how required for hi-tech niche machine building. On the other hand, it sells automation (low-cost automation appropriate to the application) as part of the solution to its customers.

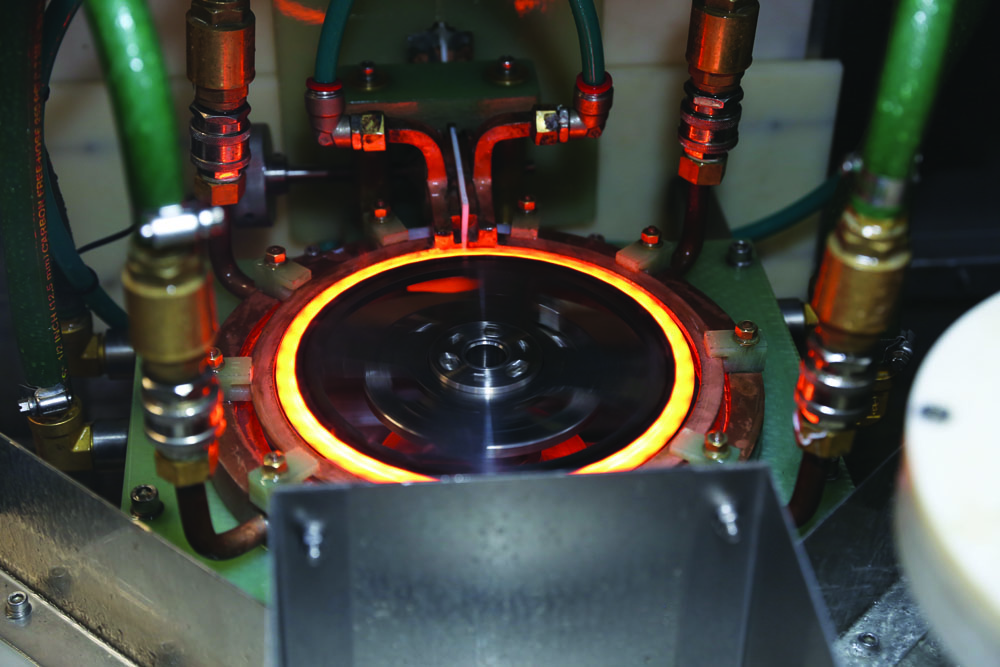

Component Heating

Challenges during lockdowns

The entire Manufacturing industry had to face many obstacles during the pandemic lockdowns and is still grappling with its effects. Chari gives insight into what GH India faced and how it emerged from the unprecedented situation. He shares, “In the initial phase of COVID-19, we had to face the hitherto unforeseen situation of Confirmed Orders on hand being put on hold by the customers. They later postponed their decision to place new negotiated orders, leading us to an uncertain future, and we were left in a ‘wait & watch’ phase.”

Once the lockdown was lifted partially and then fully, employees who had left for their native places could not return to the workplace. With uncertainty plaguing the production and supply-chain cycle, he adds that the overall mood was not upbeat.

The company implements the ‘Gurukul’ system of learning for its employees. Fresh recruits work with the team leader from the problem definition stage to the development of the solution.

“Visits by the Sales & Service Team to Customer places were curtailed, alternate channels of communication like ‘Microsoft Teams’ meetings had to be established, and the employees had to develop new skills in ‘on-line’ communications,” he adds.

Though the deliveries were put on hold, GH India continued its manufacturing activity with the available workforce and stock of materials on hand. It made extensive use of the in-house facilities (like hardening machines for trials supplemented by appropriate fixturing) to make up for the challenges posed by the pandemic.

“For GH India, working capital was not a problem since the management had the foresight to save enough for a rainy day,” Chari informs.

Poonam Pednekar

Chief Copy Editor

Magic Wand Media Inc

poonam.pednekar@magicwandmedia.in

Source: GH Induction Pvt Ltd

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe