Cleanliness in Submicrometer and Atomic Percent Range

In several industries, new and enhanced products have extremely stringent cleanliness specifications. There are stricter requirements for particulate and film-type part cleanliness as a result of changing manufacturing, joining, and coating technologies, as well as more demanding regulatory specifications. To achieve these values in series production in a process-reliable and efficient manner, not only must cleaning and drying processes meet demands and be compatible with system technology, but also software implementation and the cleaning environment must be adapted.

Whether it is production equipment for the semi-inductor industry, biotechnology, laser and sensor technology, measuring and analysis technology devices, components for accumulators and fuel cells, optical systems, or metal cutting tools, the performance and reliability requirements are exceptionally high. This necessitates not just high demands for production precision of the parts, but also for part cleanliness.

|

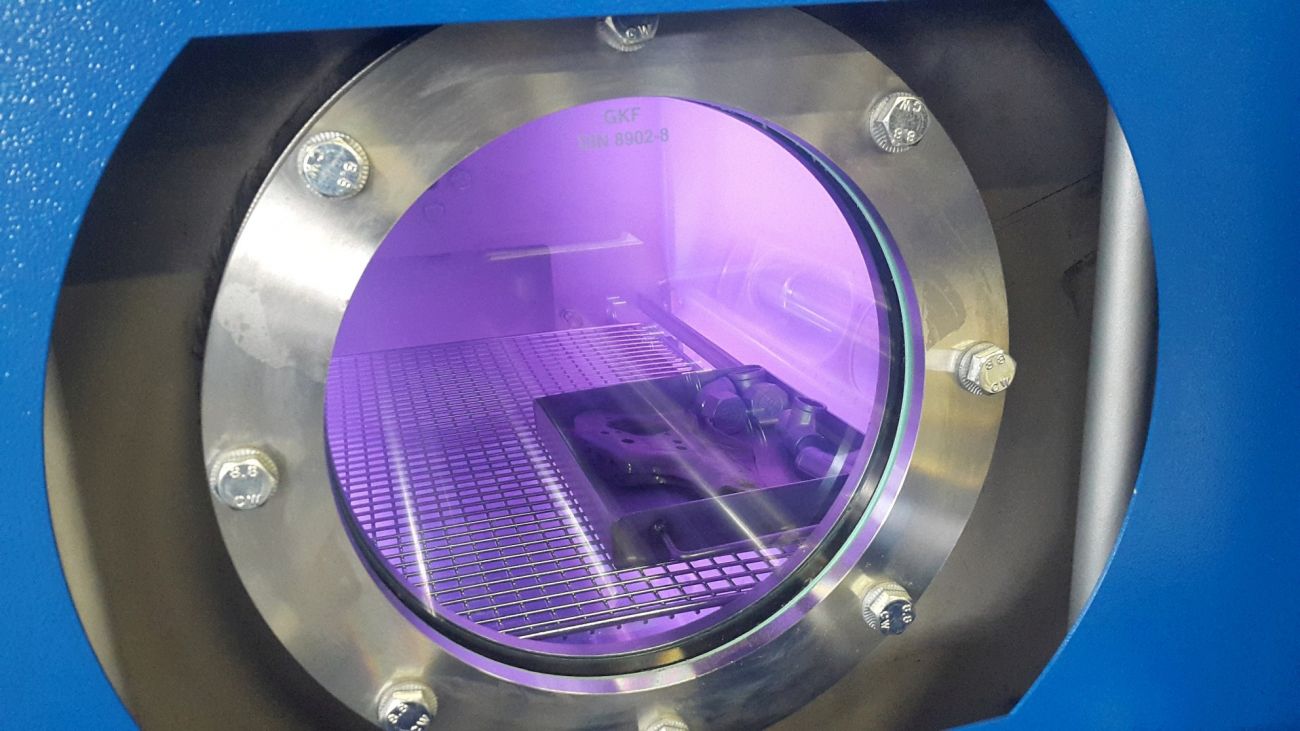

By combining wet chemical and low-pressure plasma cleaning methods for ultrafine degreasing in a single machine, the surface characteristics required for downstream coating or bonding are efficiently achieved |

Particulate and film-type contamination from manufacturing processes is a key criterion for medical technology products such as implants, instruments, cannulae, and endoscopes due to regulatory specifications. In addition, there is a trend toward miniaturization and functional integration with smaller and more complex components. As a result of these developments, particulate cleanliness specifications in the micrometer and even nanometer ranges, as well as very demanding requirements for residual thin-film contamination, must be met by an increasing number of industry sectors.

Outgassing rates for organic substances and residual moisture may also have to be met, depending on the components and/or applications, as well as limit values down to the atomic percent range when it comes to surface analyses for prohibited substances residues. There is also an evolution toward ever larger integrated manufacturing modules for the production of these miniaturized components. This introduces new challenges to cleaning processes and the machine systems necessary to implement them. As a result, the entire manufacturing chain is subjected to a series of very demanding parts cleaning tasks.

SBS Ecoclean Group of Companies covers the entire range of precision and ultrafine cleaning as a supplier of future-oriented full solutions. This allows them to tailor cleaning processes, control software, machinery, and ambient conditions to the needs and applications at hand.

|

For integration into clean rooms the ultrasonic ultrafine cleaning systems are fitted out in compliance with the applicable clean room class. |

The right system concept

The first consideration in selecting a suitable cleaning system for a specific task is whether the system will be utilized for pre-cleaning, intermediate cleaning, or final cleaning. Depending on the usage and cleanliness specifications to be met, the solution might be a chamber or multi-tank immersion machine, a flexible ultrasonic multitank machine based on standardized modules, or a customized ultrasonics-based ultrafine cleaning system. The cleaning chemicals, as well as the optimal process technologies, such as spraying, high-pressure fluid application, immersion, ultrasonic or megasonic treatment, plasma cleaning, injection flood wash, pulsated pressure cleaning (PPC), and passivation/preservation as needed, are also specifically chosen for the application and the contaminants to be eliminated.

Processes and systems for ultra-high cleanliness

UCM AG, based in Switzerland, specializes in the development of customized ultrasonic multi chamber systems and processes for ultrafine cleaning applications. The material and geometry of the parts to be cleaned, the type and quantity of contaminants, the particulate or film-type cleanliness specifications, and, where applicable, permitted outgassing rates and maximum acceptable residues of prohibited substances in the atomic percentage rate are all important considerations. Another critical consideration is the selection of appropriate cleaning chemicals and wash fluid, such as reverse osmosis water or deionized water. The materials and manufacturing methods used to build the cleaning system and automatic transport system are also chosen with dirt build-up, re-contamination, and cross-contamination prevention in mind. It is also possible to outfit it with clean room-grade components and interface with clean rooms.

|

In the immersion/spray rinse tanks specifically developed for ultrafine cleaning processes, the parts are sprayed off as they exit the bath. This enhances the rinsing result. |

Multifrequency ultrasonic systems, which provide flexible adjustment of ultrasonic frequency and intensity to the requirements of different parts to be cleaned, are standard equipment installed in precision and ultrafine cleaning systems. The PPC method comes into play with parts that present complex geometries, capillary structures, or porous surfaces, such as sintered metal components or additive manufactured components. Features such as multi-side overflow in both wash and rinse tanks, as well as immersion/spray rinse technology developed specifically for ultrafine cleaning systems, contribute to the reliable meeting of extremely stringent cleanliness specifications.

The decision on which parts are taken to which wash and rinse tanks, as well as the part-specific process parameters like temperatures, ultrasonic output and frequency, PPC intensity, and dwell time in the various wash and rinse tanks, are defined during the process development phase. Drying is generally done using infrared or vacuum technology, depending on the intricacy and heat absorption capacity of the parts. The part-specific cleaning programs that result are stored in the machine controller. In this setting, the software-controlled implementation of the cleaning sequence plays a decisive role. It ensures, among other things, that the specified dwell times in wash and rinse tanks are carefully observed and that prioritized sequences—for example, for very fragile parts—can be programmed. Cleaning trials with original parts in Ecoclean’s and UCM’s Precision Cleaning Technology Centres can determine the best system and process solution in terms of cleanliness and economic efficiency.

Image Source: Ecoclean/Philips Medical Systems/UCM / Gebr Brasseler/Zeiss

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe