REDEFINING MACHINE VISION

With its revolutionary vision technology, CynLr, a robotics deep-tech startup, is altering the field of industrial robotics and autonomous navigation, promising to simplify factory lines and empower robots to undertake any task.

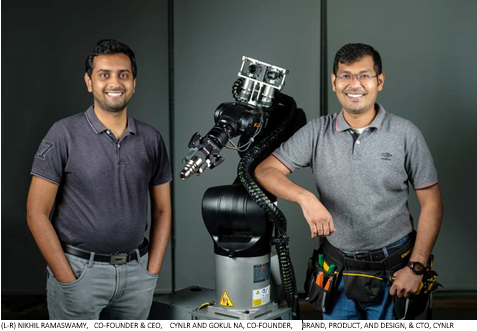

CynLr, short for Cybernetics Laboratory, is a startup in the field of robotics and deep-tech that specializes in developing advanced vision technology and intelligence for industrial robotics and autonomous navigation. Its Co-founders Nikhil Ramaswamy, CEO, and Gokul NA, CTO, share that the idea behind the company came from their experience working at National Instruments (NI), a leader in machine vision hardware and software. They identified shortcomings in the global approach to machine vision, which motivated them to establish CynLr.

“Machine vision is notorious for being unreliable, and if National Instruments had ten opportunities in machine vision from customers, they would only have a technical solution for three of them, while seven would fail,” Ramaswamy explains. This led to a soul-searching exercise by the founders to discover the missing layers, and in 2015, after four years at National Instruments, they left their jobs to start consulting in this space, applying their unique perspectives in machine vision to real-world problems.

Going ahead

In the next three years, they solved over 30 previously unsolved machine vision problems for customers in automotive and healthcare manufacturing, including GE X-Rays, Timken, and Sansera. Backed by the success of their approaches, they launched CynLr in 2019 with a seed round of Venture Capital (VC) funding to build a universal vision platform for robots. “We are VC funded. We have raised US$ 5.25 M (close to `40 crore) in venture funding from India’s Deep-Tech VCs and family offices,” Ramaswamy informs. “We will be looking to further raise our Series A round of funding for commercialization and scale later this year. Simultaneously, our customers also fund us for the collaborative design reference engagements that we are currently undertaking.”

|

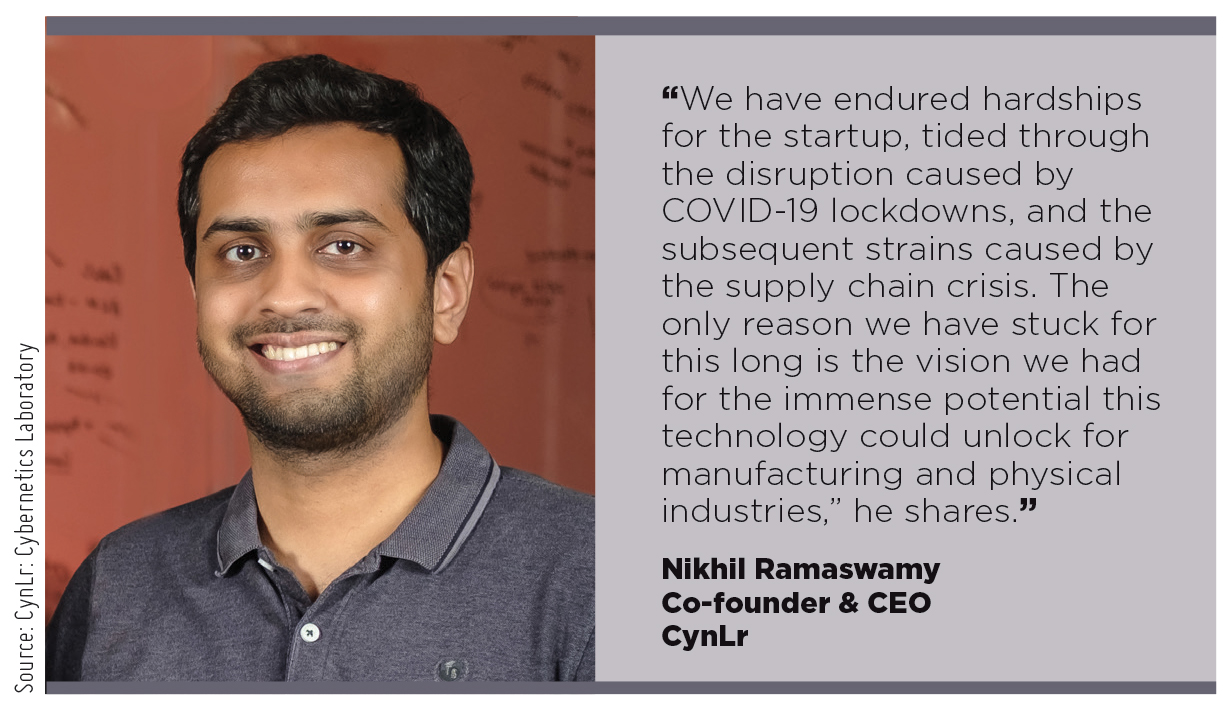

Universalization of machine vision Ramaswamy explains that he and Gokul have been chasing the opportunity to solve the universalization of machine vision for robotics use cases for over a decade now, in different organizations. “One thing that will stand out in our entrepreneurial journeys is the steadfast focus and perseverance in solving this one technological problem through peaks and troughs,” he adds. They have endured hardships for the startup, tided through the disruption caused by COVID-19 lockdowns, and the subsequent strains caused by the supply chain crisis. “The only reason we have stuck for this long is the vision we had for the immense potential this technology could unlock for manufacturing and physical industries,” he shares. |

|

The journey

Reflecting on his journey, Ramaswamy says, “Prior to CynLr, Gokul and I began our careers on the same team at NI a decade ago. We have been relentlessly pursuing this problem of making machines see and manipulate like humans.” During his time at NI, he quickly advanced to the role of Key Accounts Manager within a short span of 1.5 years and successfully doubled the company’s annual revenues from major clients such as GE, establishing it as the largest private account in India. His client portfolio included renowned semiconductor and engineering companies like Intel, Cypress, Bosch, GE, and Honeywell.

Meanwhile, Gokul excelled as a Staff Specialist in Vision, RF, and Embedded systems at NI. He catered to algorithmic requirements from Europe, Taiwan, and India, replacing ranks as the architect for the largest automated Verification and Validation (V&V) with 300K test cases from Jaguar and Land Rover. Gokul also played a significant role in architecting over 40 vision systems at NI. Additionally, he spearheaded the growth of the vision business in India by recruiting teams, structuring vision courses, and training more than 50 vision engineers to cater to customer needs.

In 2015, Ramaswamy and Gokul made the decision to leave NI and venture into the market to explore their unique approach to machine vision for object manipulation.

|

The founders, Nikhil Ramaswamy and Gokul NA, identified gaps in the approach to machine vision globally and successfully solved over 30 previously unsolved machine vision problems in automotive and healthcare manufacturing, including GE X-Rays, Timken, and Sansera. |

Industrial robotics landscape in India

|

According to Ramaswamy, India has been slow to adopt robotics because of its low manual labor wages and abundance of skilled workers. However, positive developments in Indian manufacturing are expected to increase demand for robotics in the near future. He also notes that contrary to popular belief, labor costs are not the main driver of robotics adoption, even in more advanced economies. Instead, factors such as production quality, consistency, repeatability, and traceability are the primary drivers. As a result, industries such as automotive, which require high precision and repeatability in manufacturing, have already experienced steady growth in robotics adoption. |

|

The recent trend of the Government incentivizing electronics manufacturing in India is expected to further this demand. “Even China, which rose to fame by making manufacturing cheaper for the world because labor was cheaper, eventually had to look at robotics to sustain the growth. Today, China is the largest buyer of robots, and as a single country, it buys more robots than all of Europe put together. This trend will soon happen in India too,” the CynLR CEO points out.

According to him, for India to gain and retain its brand as a quality manufacturing destination beyond just low cost, it is imperative that the industry focuses on advanced manufacturing, including robotics.

Emphasizing that the global demand for CNC machines surpasses 8,00,000 units annually, catering to the diverse needs of industries such as Automotive, Electronics, and Aerospace, Ramaswamy adds, “This number is expected to triple to 2,400,000 machines by 2030. Traditionally, feeding parts to the CNC machine and removing them after the job is done has either been manual or required manual preparation of pallets by humans so that robots can blindly handle the task. Machine Tending Automation faces the same challenges as any other robot automation—you either need the parts to be arranged manually before the robot can pick, or you have to invest in expensive, time-consuming automation projects that are not scalable.”

CynLr’s visual robots revolutionize the field by enabling robots to handle any CNC task, regardless of geometric complexity, lighting conditions, or the nature of the task.

CynLr’s vision for modular micro-factories

CynLr Vision stack makes machines instinctively see and pick any object under any ambiance without any training, just like a baby’s brain, shares Ramaswamy.

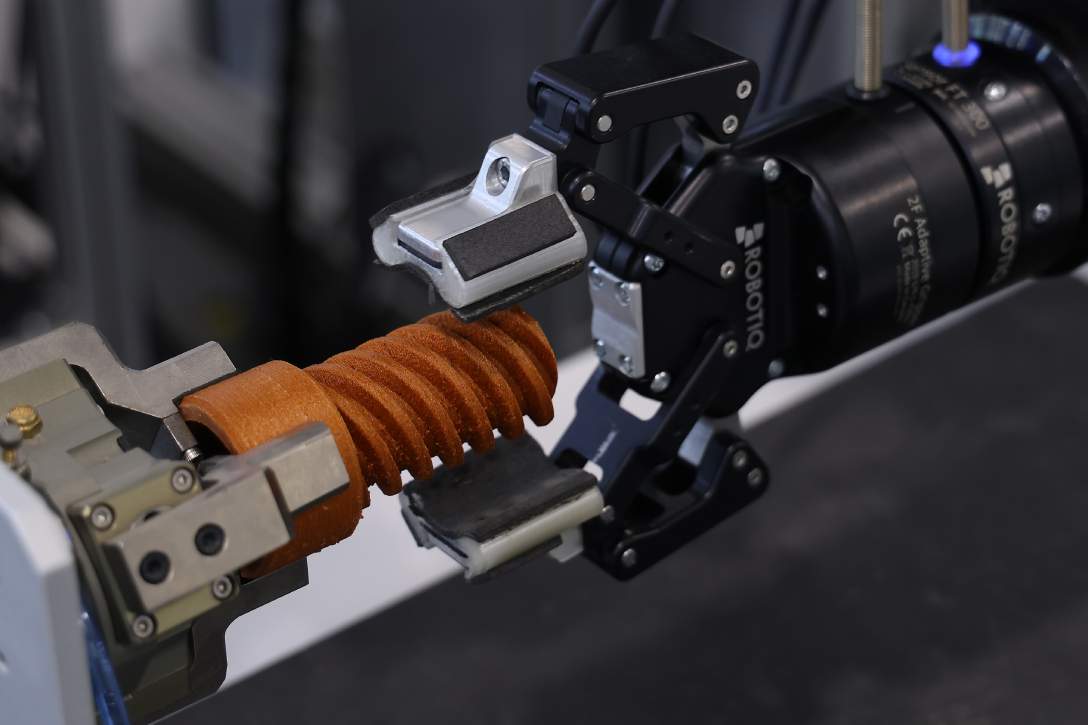

“Today, we do not have a robot that can fit a screw into a nut without slipping a thread. Even to assemble such simple parts, factories are forced to build heavily customized machines. Imagine what it would take for a robot to assemble a smartphone or a car by putting together thousands of parts with varied shapes and weights, all in random orientations,” he reasons.

|

The company is VC-funded, having successfully raised US$ 5.25 million (`40 crore) in venture funding from India’s Deep-Tech VCs and family offices. It further plans to seek additional funding through a Series A round later this year, aiming to drive commercialization and scale. |

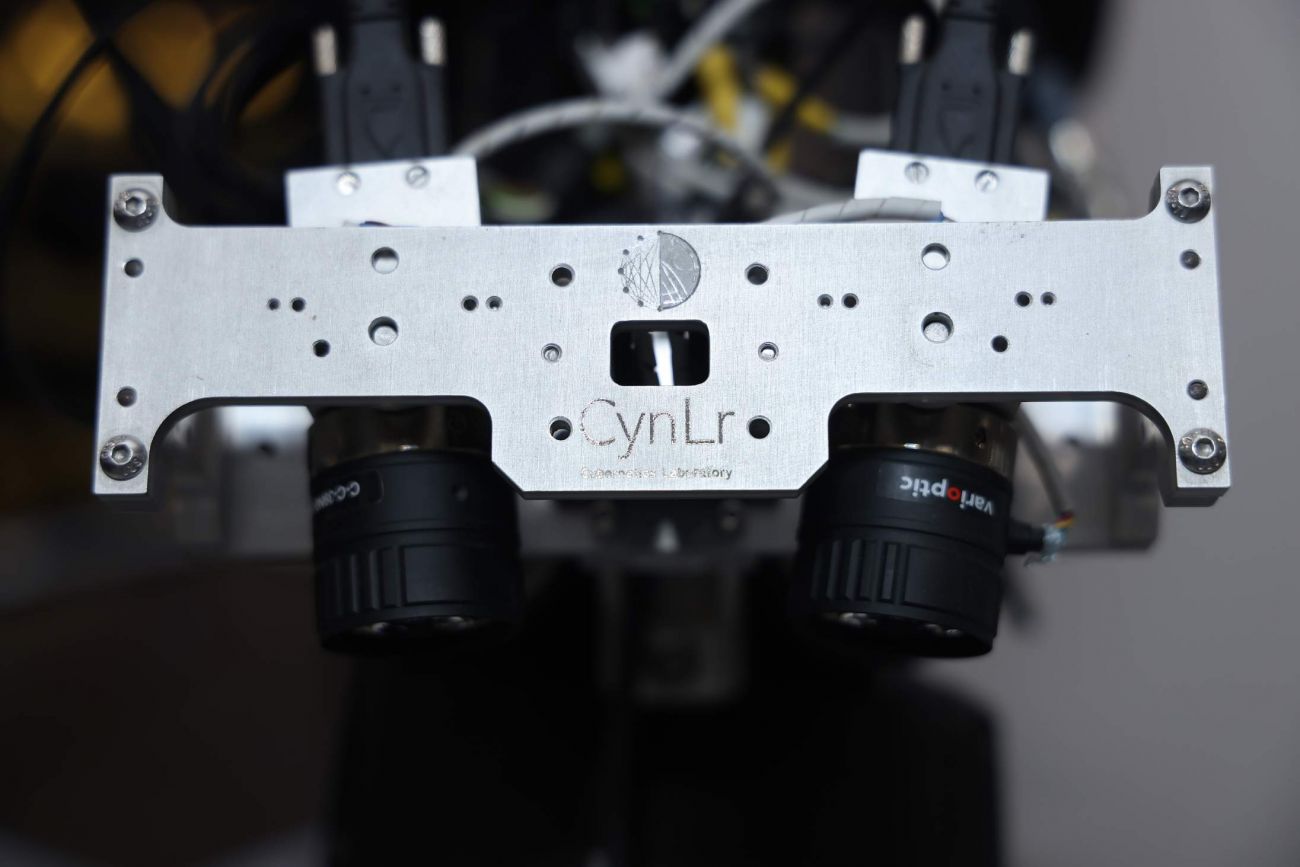

Thus, factories become complex, asset-heavy, and underutilized. CynLr enables visual robots to intuitively pick and grasp any object, even from clutter—a universal alternative to custom machines, simplifying factory lines into modular LEGO blocks of micro-factories. “Simplifying factories with robots that can pick and place any object has been a 40-year pipe dream, touted as the Holy Grail of Robotics,” he says. “To achieve this intuitiveness with objects, CynLr’s camera sees motion, color, and depth, which incidentally becomes a one-stop replacement for RADAR, LiDAR, and Camera, simplifying sensor fusion for ADAS.”

|

|

Cybernetics H. I.V.E and collaboration

With the launch of Cybernetics H.I.V.E—short for Hub for Intelligence and Vision Excellence—at Bengaluru, CynLr is set to serve as a launchpad for advanced robotics and vision research in collaboration with Ford, General Motors, Ace Micromatic, and many more. “From a tiny 250 sq ft basement space in 2019, CynLr has metamorphosized to a 52x larger, 13,000 sq ft state-of-the-art lab with the highest density of robots dedicated for vision and robotics research in the country—Cybernetics H.I.V.E.” reveals Ramaswamy.

CynLr has undergone rapid expansion, growing from a team of 8 members to a workforce of over 35 individuals, with plans to scale even further to over 70. The company has received significant attention, as evidenced by its ability to attract more than 12,000 applicants in the previous year alone. To support its research and development efforts, CynLr operates a research facility that includes 16 robot cells capable of accommodating up to 25 robots for different product and application research. Additionally, the facility boasts over 400 components and technologies, and the company has established over 200 partnerships with vendors and other entities to facilitate cutting-edge research and delivery.

|

With the launch of Cybernetics H.I.V.E, CynLr is set to serve as a launchpad for advanced robotics and vision research in collaboration with Ford, General Motors, Ace Micromatic, and many more. |

|

|

Expansion plans

“We are partnering with Indian and global CNC machine builders to offer a robot solution that they can sell as an out-of-the-box add-on to the machine to automate any tending task,” he reveals. The company is working collaboratively to define scalable reference designs for robots with vision across applications in machine tending, kitting, and assembly with India’s largest CNC manufacturer, two of the largest car OEMs in North America, and a Tier 1 manufacturer in Europe. He further adds, “We are also in advanced talks for use cases within a larger aerospace OEM, a few electronics manufacturers, and large Tier 1 auto component suppliers.”

|

Sovan Tudu |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe