Swiss Steel Group’s ‘Materials Guide’ Facilitates Find Best Steel Option for Designers Needs

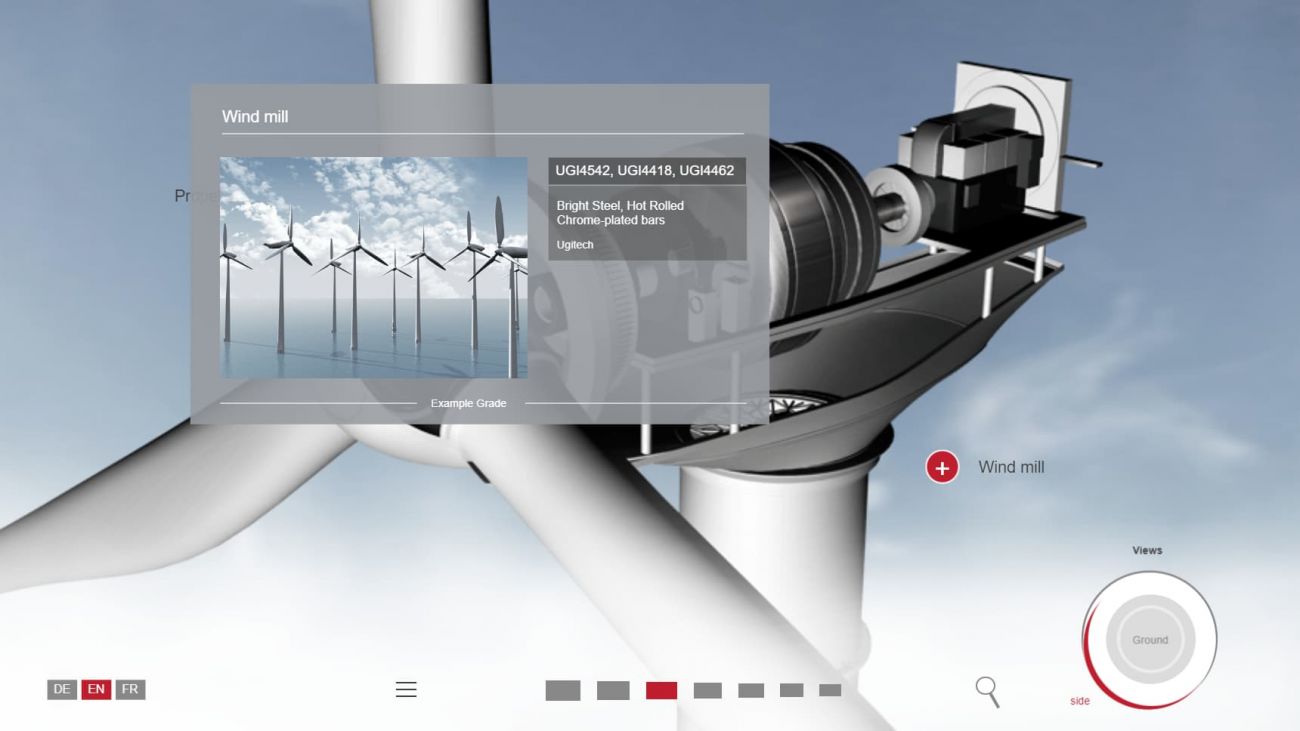

Lucerne, Switzerland – Swiss Steel Group Materials Guide comes in handy for designers seeking answers to questions like ‘Which steel grade do I use?’ and ‘Where do I find it?’. One of the leading suppliers of individual solutions in the field of special steel long products worldwide, Swiss Steel Group’s Materials Guide provides support in the search for the right steel solution for the desired requirement. The searcher gets a quick overview of the wide range of applications that the various steel grades have for the important application industries of automotive, aerospace, wind energy, and a number of other industries. At the same time, the Materials Guide gives examples based on selected steel grades.

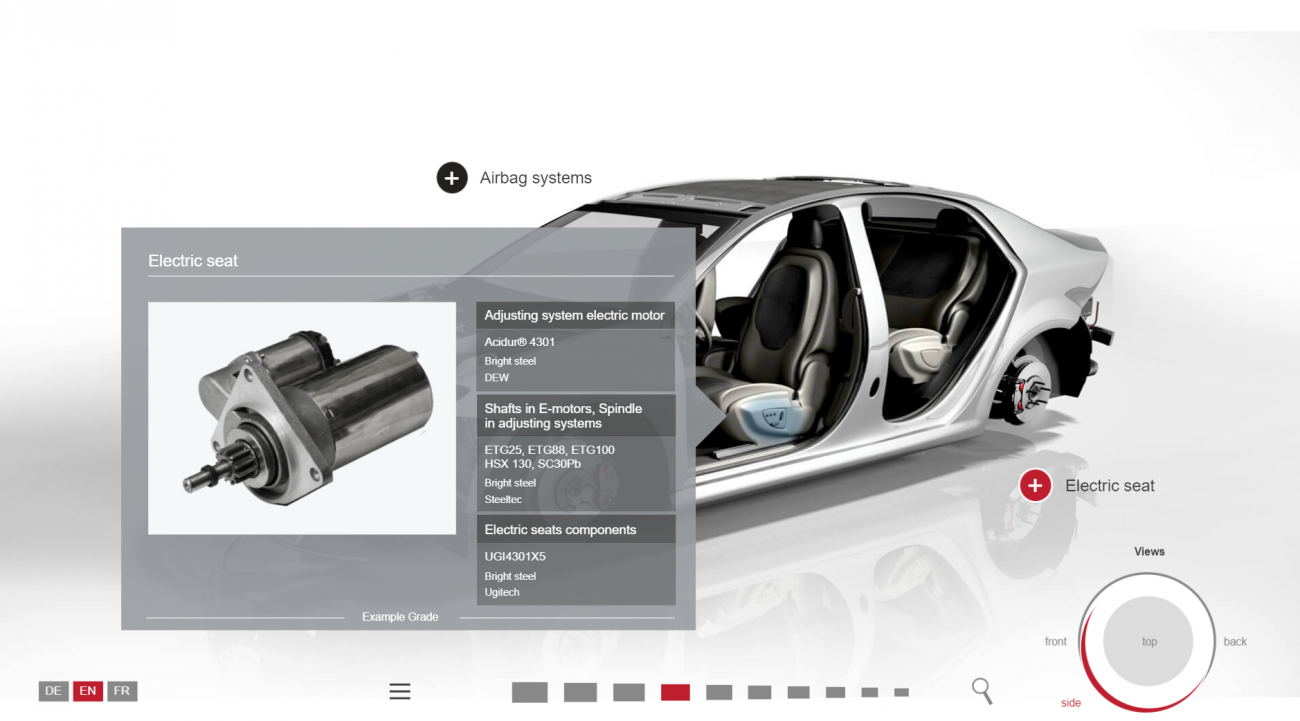

The steel grades required by the automotive industry for the following workpieces are produced at the Swiss Steel Group. The Materials Guide not only names the steel grade and its quality, but also the manufacturer within the Group: ABS, exhaust, fuel line, brake discs, differential, injection pump, springs, molds for plastic parts, gearboxes, camshafts, connecting rods, adjustment systems for electric motors, water coolers, and tools, to name just a few workpieces.

The Materials Guide is being continuously expanded to include additional steel grades and has thus become a valuable compendium for all steel users. The Materials Guide currently includes the product lines engineering steel, stainless, acid- and heat-resistant steels, and tool steel.

The Swiss Steel Group also produces special steels for the aerospace industry, where meeting requirements in terms of reliability and safety is paramount. Highly stressed parts must be made of resistant material that meets the highest standards. For the production of these special steels, the Swiss Steel Group offers modern production facilities and many decades of experience and know-how in manufacturing and processing. The aerospace industry in particular is increasingly turning to green steel to reduce its carbon footprint.

Tailor-made steel grades are also needed by the oil and gas industry. The Swiss Steel Group has developed special steel solutions for use in adverse conditions. These are steels that withstand the highest demands in terms of strength, wear resistance, temperature, or corrosion resistance. The Swiss Steel Group covers a wide range of applications for both the onshore and offshore sectors, as well as for the extraction of conventional and alternative resources. With high-tech products, the Group supports efficient energy and resource extraction, for example, with blowout preventers, amagnetic heavy bars, steel for pump blocks in production facilities, and fracking blocks, valves, fittings, and filters. The Steel Group's broad portfolio of steel grades for oil and gas exploration includes low- and high-alloy engineering steels, ferritic, martensitic, high-alloy austenitic and duplex stainless steels, and magnetic steels. In its newest category, ‘Molds’ designers can find everything about extrusion, die forging, die casting, and injection molding.

Image Source: Swiss Steel Group

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe