COMBATING CORROSION CAUSES

A peek into Professor D Senthilkumar and his research team’s groundbreaking project of developing superhydrophobic surface textures using IoT systems.

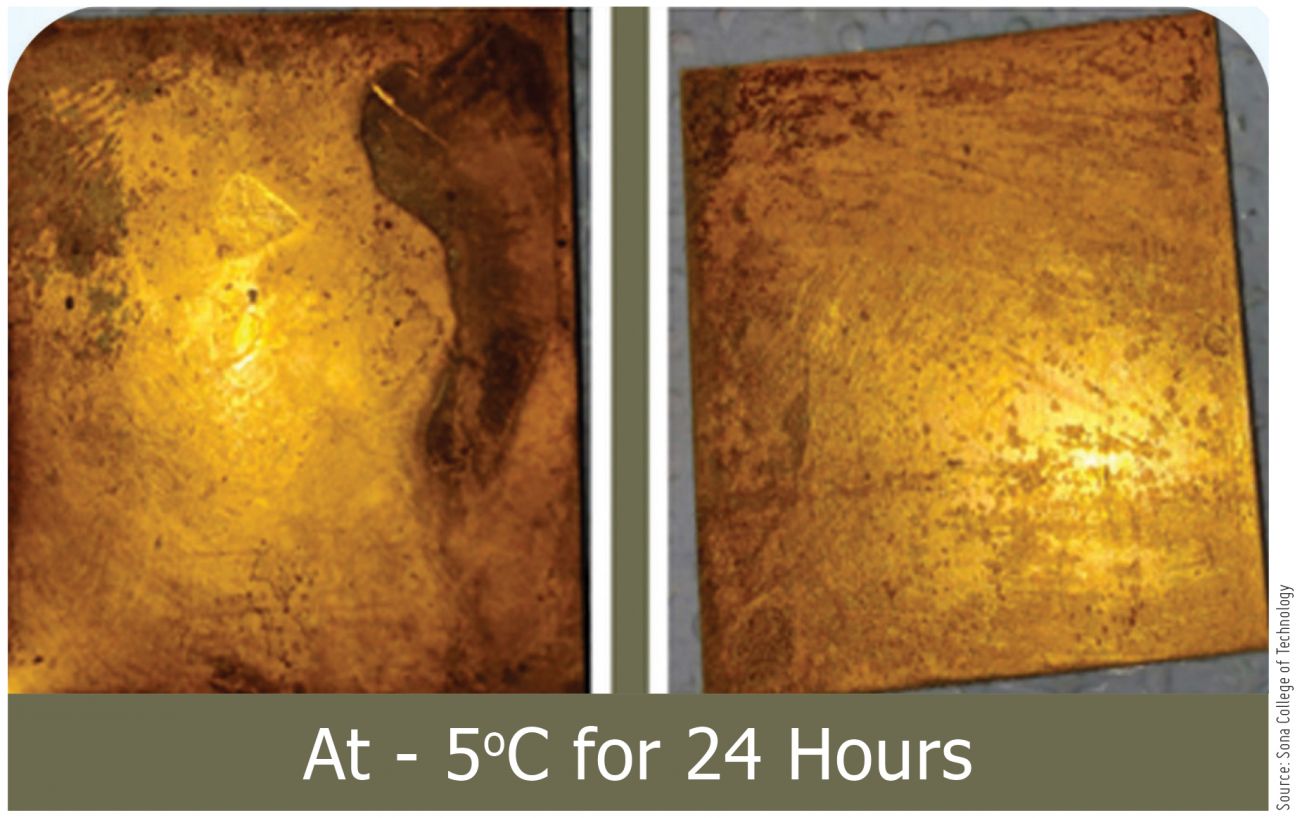

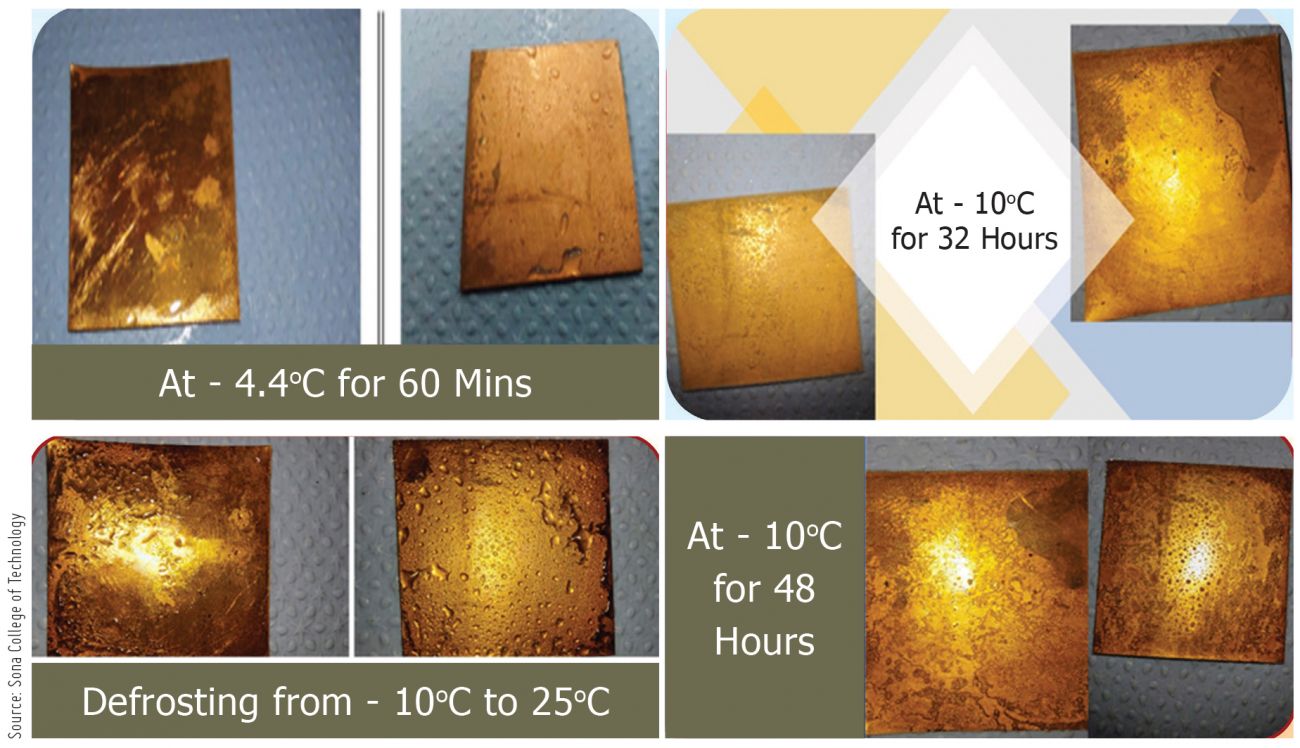

Professor D Senthilkumar and his research team at Sona College of Technology are dedicated to the development of a groundbreaking project titled ‘Developing Superhydrophobic Surface Texture by Using IoT Systems.’ Their focus lies in addressing various challenges related to corrosion resistance in steel rods used in ocean bridge construction, construction steel rods, self-cleaning materials, defrosting frozen ice in fridges, and preventing corrosion in AC water separator tubes.

Validation of the problem

To validate the problem at hand, extensive data collection and analysis have been conducted. Through surveys and evaluation of research papers, no claims have been found regarding IoT-based acid etching. The team emphasizes the following differences compared to earlier methods:

- Enhanced accuracy in the surface finish;

- Notability of the process;

- Reproducibility of the coating, wherein the IoT-based and automated system ensures correct concentration levels based on predefined values. This system generates consistent and hydrophobic coating profiles, making it potentially patentable.

|

The foremost objective of the project is to manipulate IoT-based system for acid etching and to promote superhydrophobic surfaces with superior surface finish. The IoT system ensures precise and automated coating processes for the substrate. |

Solution to address the problem

The proposed solution revolves around introducing oxide/polymer-based superhydrophobic surfaces and coatings that exhibit exceptional water repellence. The project begins with an exploration of hydrophobic and superhydrophobic behaviors, followed by the description of four phases of superhydrophobic technology.

Various methods can be employed for structure development, such as acid erosion, laser cutting, EDM, vaporization of

the layer surface, and focused ion beam machining. It is crucial to consider these factors to prevent destructive layer functionality and incomplete etching. Patentability does not apply to hydrophobic elements under acid etching.

The project offers several benefits, including the construction of ocean bridge steel rods for pillars, corrosion resistance for steel gates and other applications, corrosion resistance for AC water disposal tubes, and corrosion resistance for refrigeration cooling air supply tubes.

The foremost objective of the project is to manipulate IoT-based system for acid etching and to promote superhydrophobic surfaces with superior surface finish. The IoT system ensures precise and automated coating processes for the substrate.

|

Dr D SENTHIL KUMAR Professor / HOD Department of Mechanical Engineering Sona College of Technology senthilkumard@sonatech.ac.in |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe