FORTIFYING DEFENCE CAPABILITIES

Innovation in materials has emerged as a critical enabler in achieving several national objectives such as self-reliance and innovation in the defence sector and ensuring the safety of soldiers. CUMI, with its focus on material science, nanotechnology, and polymer chemistry and commitment to research and development, is pushing the boundaries of material technology and creating new-age materials that hold the potential for breakthroughs in defence applications.

he Ministry of Defence in India recently approved the fourth Positive Indigenisation List (PIL), thereby underscoring the nation’s commitment to self-reliance and innovation in the Defence sector. This list, consisting of more than 900 defence components and sub-systems, marks a significant stride towards reducing dependence on imports and fostering indigenous manufacturing, technology, and job creation.

In the face of an ever-changing and volatile world, ensuring the safety of soldiers stands as a paramount concern. Innovation in materials has emerged as a critical enabler in achieving these objectives.

Role of material science in defence

From personal armor that protects soldiers from high-velocity projectiles and explosive devices to advanced ceramics and ballistics solutions in vehicle armor, materials science is a lynchpin in enhancing protection, performance, and battlefield advantage.

The landscape of defence materials has evolved significantly, driven by the demand for tough, lightweight, and specialized solutions. Innovations in armor, stealth, and nanotechnology-enabled materials have revolutionized the capabilities of defence equipment, paving the way for advanced protection and resilience against emerging threats. Materials like silicon carbide and alumina have elevated the lethality and payload capacity of missiles, while carbon fiber reinforced polymers (CFRP) have transformed the agility and maneuverability of unmanned aerial vehicles (UAVs). The ability to develop and harness these materials is central to achieving superiority on the global stage.

CUMI’s innovations and performance in defence

With a focus on material science, nanotechnology, and polymer chemistry, CUMI has emerged as one focusing on creating new-age materials that hold the potential for breakthroughs in defence applications. CUMI’s dedication to research and development aligns seamlessly with the nation’s drive for self-reliance and indigenous manufacturing.

|

Initiatives like the Centre of Excellence at the Digital University of Kerala exemplify CUMI’s commitment to exploring the transformative potential of materials like Graphene and propelling India’s leadership in cutting-edge materials. |

CUMI’s contributions extend beyond research, encompassing collaborations with academia and industry. These partnerships serve as crucibles for innovation, harnessing the collective expertise of both sectors to push the boundaries of material technology. Initiatives like the Centre of Excellence at the Digital University of Kerala exemplify CUMI’s commitment to exploring the transformative potential of materials like Graphene and propelling India’s leadership in cutting-edge materials.

Applications of innovative materials in defence

The integration of advanced materials into various defence applications is redefining the capabilities of armed forces:

Personal armor

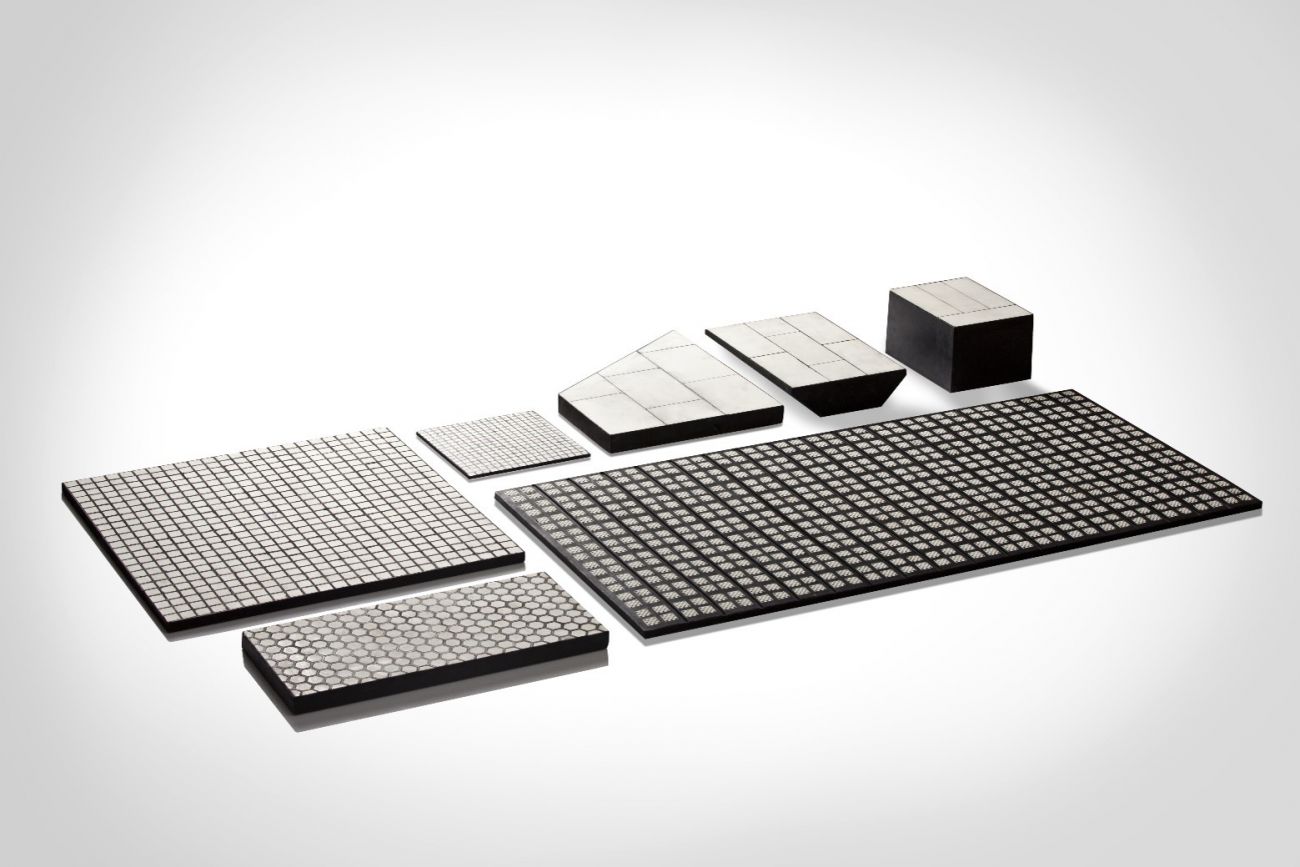

Personal armor, fortified with ultra-fine silicon carbide, high-strength aramid fibers, and zirconia-toughened alumina, disperse and absorb energy from threats, ensuring the safety of soldiers. CUMI produces high-purity, ultra-fine silicon carbide sub-micron powders, essential for their advanced ceramic compounds. These powders are a crucial element in CUMI’s dependable ballistic solutions. Unlike traditional heavy metal armors, CUMI’s modern alternatives utilize lightweight ceramic materials, such as alumina, silicon carbide, and zirconia-toughened alumina in the form of tiles/segments/panels, etc. These ergonomic solutions are customizable in size and shape, providing effective and comfortable protection.

Vehicle armor

In vehicle armor, advanced composites are revolutionizing protection by safeguarding against blasts and ballistic threats, enhancing the mobility and survivability of troops. CUMI specializes in ballistic protection for vehicle floor and side panels, as well as offering hybrid composites for safeguarding vehicle undercarriages against blasts. The advanced lightweight ceramic materials are engineered to provide unparalleled ballistic and blast-proof protection for armored vehicles. CUMI’s ceramic product line for battle tanks encompasses hatches, top deck covers, side plates, and fuel tank covers.

Unmanned aerial vehicles

Unmanned aerial vehicles (UAVs) owe their agility and maneuverability to CFRP, which offer exceptional strength-to-weight ratios. CFRP not only extend flight performance and operational range but also reduce power consumption, increase payload capacity, and enhance stealth capabilities. With a rich legacy spanning over fifty years, CUMI’s Composites Manufacturing Division boasts extensive expertise in designing, manufacturing, and testing composites. From landing gears to payload holders, CUMI leverages state-of-the-art composite technology for Unmanned Aerial Vehicles (UAVs). Its offerings encompass a range of solutions, including CFRP tubes, sheets, and tailor-made composite structural components designed specifically for UAVs.

CUMI also recently partnered with drone maker ideaForge Technology to develop nanomaterial-reinforced composite parts for drones. These materials offer features such as higher mechanical strength, greater toughness and stiffness, better electrical and thermal conductivity, superior fire retardancy, and higher barrier to moisture and gases. Nanocomposites also offer unique design possibilities, which offer immense potential in creating materials with desired properties for specific applications. The use of the appropriate nanomaterials can help build drones that are smaller, lighter, stronger, and more durable, among others.

Missiles

Modern defence relies on advanced ceramics in missiles for precision targeting and enhanced capabilities. Advanced ceramics offer strength, hardness, and temperature resistance, enabling lightweight yet potent missile systems. Aerospace and Defence sectors experience progress with microwave ceramics, driven by leaders like CUMI. Ceramic radomes protect critical electronic equipment from extreme temperatures during the flight of the missile. Other innovations span structural ceramics for crucial missile parts, metallized ceramics for triggered spark gaps, and vital spare components like ceramic fasteners, highlighting ceramics’ transformative role in these industries.

Futuristic materials: Graphene and Phase Change Materials

The trajectory of material science innovation extends beyond the horizon, encompassing futuristic materials, like Graphene and Phase Change Materials (PCMs). Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, boasts extraordinary properties that promise revolutionary advancements in various industries, including Defence. Its exceptional strength, thermal conductivity, and electrical conductivity make it a potential game-changer in lightweight armors, energy storage systems, and even advanced electronics for military applications.

PCMs, with their ability to store and release thermal energy, offer intriguing possibilities for enhancing soldiers’ comfort and survivability in extreme conditions. By absorbing excess heat during periods of high temperature and releasing it when temperatures drop, PCMs can contribute to innovative clothing and gear, enabling soldiers to operate effectively in diverse environments. PCMs are also being used to build barracks for soldiers serving in areas with extreme weather conditions.

Towards self-reliance and innovation

In the dynamic arena of defence, the role of material science remains paramount in ensuring the safety, efficacy, and superiority of armed forces. The recent strides made by India in pushing for the indigenization of defence materials reflect a commitment to self-reliance and innovation. CUMI’s innovations in material science underscore the nation’s potential in creating cutting-edge solutions for defence challenges. The applications of innovative materials, from advanced ceramics for missiles, lightweight ceramics for personal armor to composites for UAVs, have reshaped the landscape of defence capabilities.

|

Unlike traditional heavy metal armors, CUMI’s modern alternatives utilize lightweight ceramic materials, such as alumina, silicon carbide, and zirconia-toughened alumina in the form of tiles/segments/panels, etc. |

As we peer into the future, the evolution of material science holds immense promise. Graphene and PCMs offer a glimpse of the transformative potential that lies ahead. By nurturing collaborative efforts between the Government, private sector, and academia, India is poised to solidify its position as a leader in cutting-edge materials, fortifying its defence capabilities and securing a safer tomorrow for its citizens.

|

SUBBU VENKATACHALAM Head of Marketing Carborundum Universal Ltd |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe