INNOVATIONS FOR SIMPLIFIED ADAPTABILITY

With the increased demands in the automation industry today, handling solutions must be quick to integrate, flexible to redesign, completely open regarding connectivity, and ensure safe gripping. Here’s a list of a few boasting the same qualities…

The automation experts at SCHUNK have paid utmost heed to the increased demands in the Automation industry and, as a result, have come up with new product innovations that offer a maximum level of flexibility, enable networked processes in every industry, and include customization options that are easy for anyone to implement.

EGU and EGK — Robust mechatronic gripping modules

The new mechatronic grippers EGU and EGK grippers have integrated gripping force maintenance with workpiece loss detection. No referencing is required during integration or after start-up. This saves time and reduces commissioning work. With permanent position detection, users always keep absolute control over their processes. SCHUNK offers the components with all the common communication interfaces, PLC function modules, and plug-ins from leading robot manufacturers. This means that they can be integrated quickly and easily without any additional gateways or programming.

PGL+P — Pneumatic gripper with potential

With the new PGL+P, SCHUNK is introducing a flexible and robust powerhouse that shines above all with increased safety. The pneumatic gripper is the first in the world to have certified safe gripping force maintenance. The pneumatic universal gripper in five sizes offers a unique performance package of stroke, force, and connectivity, making it perfectly suited for handling tasks where flexibility is required. Due to its large jaw stroke per finger, users can handle a wide range of parts with just one gripper. This saves investment costs and is particularly interesting for small batch sizes and high part variance, such as in machine loading and assembly.

|

There is a rising trend towards greater automation in all major industries like Automotive, Life Sciences, E-mobility, and Packaging. An important reason for this is the lack of skilled workforce |

|

The pneumatic gripper PGL+P |

ADHESO is a bionically inspired gripper |

|

MTB Kits for workpiece handling and clamping |

REMENDO automates deburring, polishing and grinding processes |

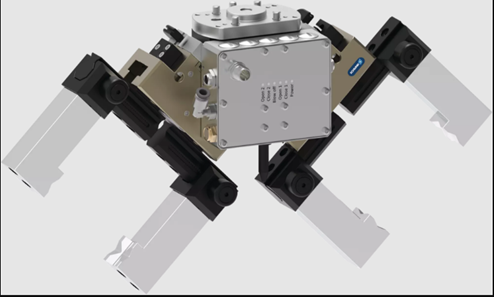

ADHESO — Bionically inspired gripper

ADHESO gripper technology is based on the principle of adhesion and uses intermolecularly acting Van der Waals forces to handle various workpieces.

SCHUNK’s application experts take advantage of these benefits and develop customer-specific adhesive grippers with ADHESO gripper technology. Due to the high variability of the adhesive structures, grippers with ADHESO technology can be directly tailored to the requirements of applications in Packaging, Pharma, and Electronic industries.

The advantages include • Gripping without residue; • Sensitive gripping without mechanical force; and • No external power supply.

MTB Kits — Application kits for seamless integration of EOAT

The MTB application kits enable quick and easy implementation of automated machine loading. The specific application kits take on the important key role of workpiece handling and workpiece clamping. They seamlessly fit into the machine environment. One can choose the right solution for their application from three application kits MTB. The single gripper kit, the double gripper kit; and the clamping force block kit are available.

REMENDO — From manual to automated machining of workpieces

REMENDO Product portfolio of SCHUNK allows one to automate the deburring, polishing and grinding process.

Manual machining of workpieces with hand tools is often associated with putting ergonomic strain on employees. In addition, health risks are often incurred due to fine particle emissions such as abrasive dust or chips. The changing over to automated machining minimizes these risks but also creates surplus values.

There is a rising trend towards greater automation in all major industries like Automotive, Life Sciences, E-mobility, and Packaging. An important reason for this is the lack of skilled workforce. Hence, more and more small and medium-sized companies are taking steps towards automated systems and preferring simple and flexible solutions.

|

ASHWIN UDAYASHANKAR National Sales Manager - Gripping Technology & Automation Technology SCHUNK Intec India Pvt Ltd |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe