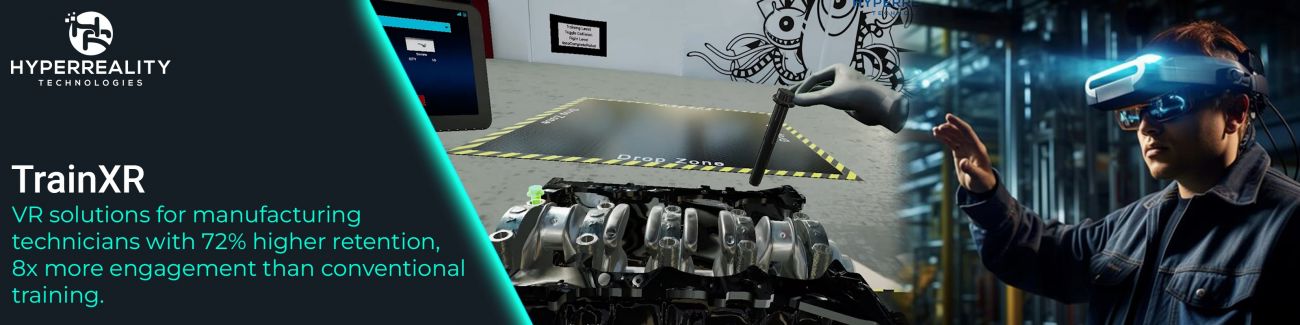

Hyperreality Technologies’ TrainXR

VR Training Platforms

Hyperreality Technologies’ TrainXR is an effective ready-to-go VR training platform for assembly, service procedures, and safety training in the manufacturing domain, enabling over 75 percent retention, 40 percent less training time and 8 times more engagement compared to traditional classroom-based approach.

Manufacturing enterprises face various technical training challenges in training that require practical hands-on assembly/disassembly procedures, like reduced effectiveness, limitations in classroom training, engagement challenges for video, presentations etc., limitations in providing practical assembly sessions, and difficulty in logistics for repeated training or updation. Even after providing training, the employers find it difficult to measure and analyze the effectiveness/results of training given to the employees.

The current industry approach is to make custom-built modules that are expensive rather than the platform approach where the same set of parts can be combined to create as many training modules by the trainers themselves giving cost and wider adoption. TrainXR follows a platform approach built specifically for trading and manufacturing scenarios, wherein using the constituent ‘smart parts’, trainers can create simulations by themselves without the need for skilled 3D, animation of programming expertise. The company believes this will help increase the adoption of VR training modules due to ease and lower cost compared to the current industry approach.

For creating digital twins for the manufacturing enterprise domain, TrainXR’s VR assembly and training platform framework allows users to create and assemble digital twin replicas of machinery from components and offer assembly training in VR. This allows the user to simulate the entire assembly or manufacturing process before actually using the physical work equipment. Further, advanced analytics provides powerful insights of how the task is being done by each trainee and baselines. It provides the following features:

- Part assembly procedures for easy and quick creation of assembly/disassembly

- instruction modules;

- Self-paced practice mirroring the real-world equipment, tools and scenarios as

- many times as required;

- Measurement & Analytics for the time taken to assemble or perform every step;

- Track performance improvements;

- Self-author simulations without the need for skilled 3D expertise;

- Publish to Web, Mobile, and VR;

- LMS and Enterprise integrations available.

Details:

Hyperreality Technologies Pvt Ltd

www.hyperrealitylabs.com/

Hall & Stall: 5/B-121

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe