Heading in the Right Direction

The fourth industrial revolution has ushered in technologies that are redefining the manufacturing ways. As the new and emerging technologies such as the industrial internet of things, advanced robotics, artificial intelligence and additive manufacturing are unfolding their impact on the manufacturing processes, manufacturers are increasingly making aggressive moves to adopt them in their pursuit of enhanced efficiency and productivity gains.

The trend can majorly be observed in the country’s key automotive sector, which is undergoing a transformative change in the process of catering to its end users’ demands that include greater connectivity and innovative solutions for safety, ease of use, and infotainment. Environmental regulatory norms and cost-competitiveness are other key factors compelling auto manufacturers to resort to these breakthrough technologies. “In India, disruptive concepts like IoT and Industry 4.0 are still at a nascent stage. However, with a connected world, sooner rather than later, this revolution will be staring at us in the face,” says Nirmal Minda, President, Automotive Component Manufacturers Association of India (ACMA).

The Indian auto sector is witness to a phenomenal growth. There have never been such myriad options in the models of cars, bikes and commercial vehicles launched by auto companies. Along with being a major consumer of automobiles, India is also a major exporter of auto components to many countries, which is another factor for the growth of the Indian automotive industry and component manufacturing industry.

A fillip to the machine tool sector

The machine tool industry and the automotive industry have always been working hand in glove with each other. Since over 50 percent of the Indian machine tool industry’s production gets supplied to the country’s automotive segment alone, the latter primarily drives the machine tools’ growth. As the machine tool industry continues making progress and heads towards sophisticated CNC machines, it must also acknowledge the demands being made by its major user segment which primarily comprise technological upgradation.

“We are living in exciting times. There are innovative solutions getting developed for the new challenges in India and other parts of the globe. Companies are adopting newer technologies not only in machines, but also in the entire manufacturing ecosystem to enhance productivity,” says Ravi Raghavan, CEO, Bharat Fritz Werner Ltd, pointing to the work in progress.

The Front Axle Beam machine launched by BFW is an import substitute for the growing demands of the commercial vehicle manufacturers.

Auto players upping their game

The machine tool manufacturers are closely observing this digital shift in the auto sector since they are the ones who will have to ensure that the machine tools are modernized to serve the auto companies with the machines that they require. “Companies are moving from mass production to smaller lot multi-model manufacturing. There is a great focus on technology driven productivity and this excites us because we have been developing this aspect as a strength for some time now,” shares Raghavan.

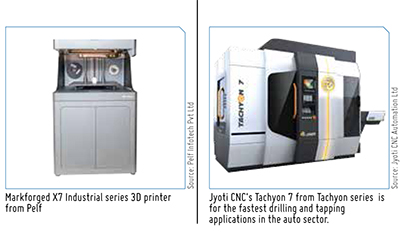

Ajinkya Huddar, CEO & Managing Director, Pelf Infotech Pvt Ltd, notes, “Conventional manufacturing system calls for a close-knit combination of CAD-CAM that encapsulates design setup, moulding, tooling and allied pre-requisites, whereas Industry 4.0 emphasizes predominantly on smart manufacturing techniques like Additive Manufacturing (3D Printing) using smarter and non-conventional material like composites in addition to plastic and metal that can really reap dividend in the long term. The global auto sector has started leveraging the benefits of 3D Printing for mainstream production. Although its adoption is not as aggressive in India, but the auto companies and the ancillaries have started following their global peers,” he adds.

Since most Indian auto manufacturers are working on electrifying their products, the economy is likely to see a shift from being a combustion-driven market to a battery and cell-driven one, remarks Umesh L, CEO, Ace Manufact

uring Systems Ltd (AMS). “Another change is the large extent of work that is being done in automating the entire value chain including real-time material planning, resource allocation, and production technology. Various IoT solutions are being deployed by automotive industries in enhancing their production processes,” he adds.

According to Punit Gupta, Managing Director, Blaser Swisslube India Pvt Ltd, Change Management has become a key task due to faster changes coming in technologies from multiple directions and dimensions. Simple to complex digitization is creating a huge impact on manufacturing, with industry learning to be more agile. New technologies have also enabled people’s efforts to be environmentally-conscious.

Machine tool players going all out

The machine tool players of the country are doing their best, chipping in with their productivity enhancing solutions and ensuring that the auto companies get an equal competitive edge as their global peers.

To support its auto customers, BFW has started manufacturing intelligent machines and moving towards smart manufacturing. “We have successfully developed an IoT platform, IRIS, to address these needs. We have installed IRIS in some of our machines delivered to a number of corporate clients and this will be part of all our new machines,” informs Raghavan. IRIS is an offering that spans wide beyond the auto sector and adds a breakthrough dimension in terms of productivity solutions from machine tool companies.

He then elaborates on what he calls BFW’s strength, which are solutions which have the most complex mix of special purpose and standard machines, “We have launched the Front Axle Beam machine, an import substitute, for the growing demands of the commercial vehicle manufacturers. This machine is completely automated which handles heavy forged components with safety and in a single setup.”

Blaser’s Liquid Tool approach has led to its customers in the auto sector achieve cut time reductions in the range of 5 to 15 percent, and tool cost reductions in the range of 20 to 40 percent. “We did more than 200 projects last year in India wherein we could document the positive impact of Liquid Tool in increased competitiveness and productivity,” says Gupta.

Blaser’s Liquid Tool approach has led to its customers in the auto sector achieve cut time reductions in the range of 5 to 15 percent, and tool cost reductions in the range of 20 to 40 percent. “We did more than 200 projects last year in India wherein we could document the positive impact of Liquid Tool in increased competitiveness and productivity,” says Gupta.

Huddar shares Pelf’s product portfolio, “We have been catering to a plethora of industry verticals from Automotive to Aerospace to Product Development to Defence to Medical Electronics etc. for the last two decades with our wide range of products including CAD, CAM, CAE, CFD, CAI, Reverse Engineering, and Additive Manufacturing based on end-user requirements.”

It’s been 25 years for AMS to be one of the preferred machine tool builders for most of the auto OEMs and auto component manufacturers. “We provide various productivity enhancing solutions such as large capacity tool changers with sister tool programming features, automatic pallet changers to minimize the component load unload times, index tables and rotary tables to reduce the number of setups in machining, software features for tool life monitoring, in-process measurement and corrections for certain specific critical applications etc.,” says Umesh.

The company has also developed certain special products specifically for the high-volume automotive market such as the twin spindle machining centers in different tool sizes and strokes suiting the applications. AMS also offers automation solutions to further enhance the productivity of the process by reducing the human intervention and allowing the machines to work during breaks.

Jyoti CNC offers total solutions coupled with automation with its products to suit individual needs. “We have served many customers from the auto sector with complete tooled-up solutions to turnkey projects, and our aim is to keep enhancing our solutions depending on the needs of our customers, rather than offering vanilla machines to all,” shares Himanshu P Shaparia, Vice President – Sales, Jyoti CNC Automation Ltd.

Jyoti CNC offers total solutions coupled with automation with its products to suit individual needs. “We have served many customers from the auto sector with complete tooled-up solutions to turnkey projects, and our aim is to keep enhancing our solutions depending on the needs of our customers, rather than offering vanilla machines to all,” shares Himanshu P Shaparia, Vice President – Sales, Jyoti CNC Automation Ltd.

Challenges on the way

Apart from access to and deployment of requisite affordable technologies, one of the major challenges, Minda foresees, is that of building a skilled workforce that will allow the change to succeed. “The transition to adapt to the new industry environment will also bring forth issues such as data protection and security, knowledge about proprietary production, high degree of reliability and stability, which is required for successful cyber-physical communication. Moreover, avoiding technical problems that could cause expensive production outages will need to be addressed,” he adds.

Gupta puts forth his view, “Competitiveness will challenge the manufacturers more due to the complexity emerging in the global world either due to a protectionism trend or new emerging technologies which are disruptive or innovative.” He stresses on a holistic approach which he feels would be extremely important and interesting to drive the competitiveness and productivity.

Optimism abounds

It’s the nature of science to always be advancing. Technologies evolve and get advanced simply to improve processes and products. With some challenges, the advanced production technologies of today promise much more opportunities. “With the introduction of these new technologies, new skill sets would be required in the field of design, operations as well as other elements of the auto value chain in the next few years. Low-skilled labour jobs which mostly include repetitive routine job such as painting, welding etc. will give way to higher skills such as supervising, designing, robotics, programming and maintenance etc. Enabling and equipping the workforce with appropriate skills will further increase their efficiency with the added benefit of increased revenues, market share and profits,” sums up Minda pointing to a brighter tomorrow.

It’s the nature of science to always be advancing. Technologies evolve and get advanced simply to improve processes and products. With some challenges, the advanced production technologies of today promise much more opportunities. “With the introduction of these new technologies, new skill sets would be required in the field of design, operations as well as other elements of the auto value chain in the next few years. Low-skilled labour jobs which mostly include repetitive routine job such as painting, welding etc. will give way to higher skills such as supervising, designing, robotics, programming and maintenance etc. Enabling and equipping the workforce with appropriate skills will further increase their efficiency with the added benefit of increased revenues, market share and profits,” sums up Minda pointing to a brighter tomorrow.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe