NAVIGATING SENSOR MARKET INSIGHTS

While the manufacturing market is surging with industrial IoT and smart tech, predictive maintenance is holding profit potential for industry players.

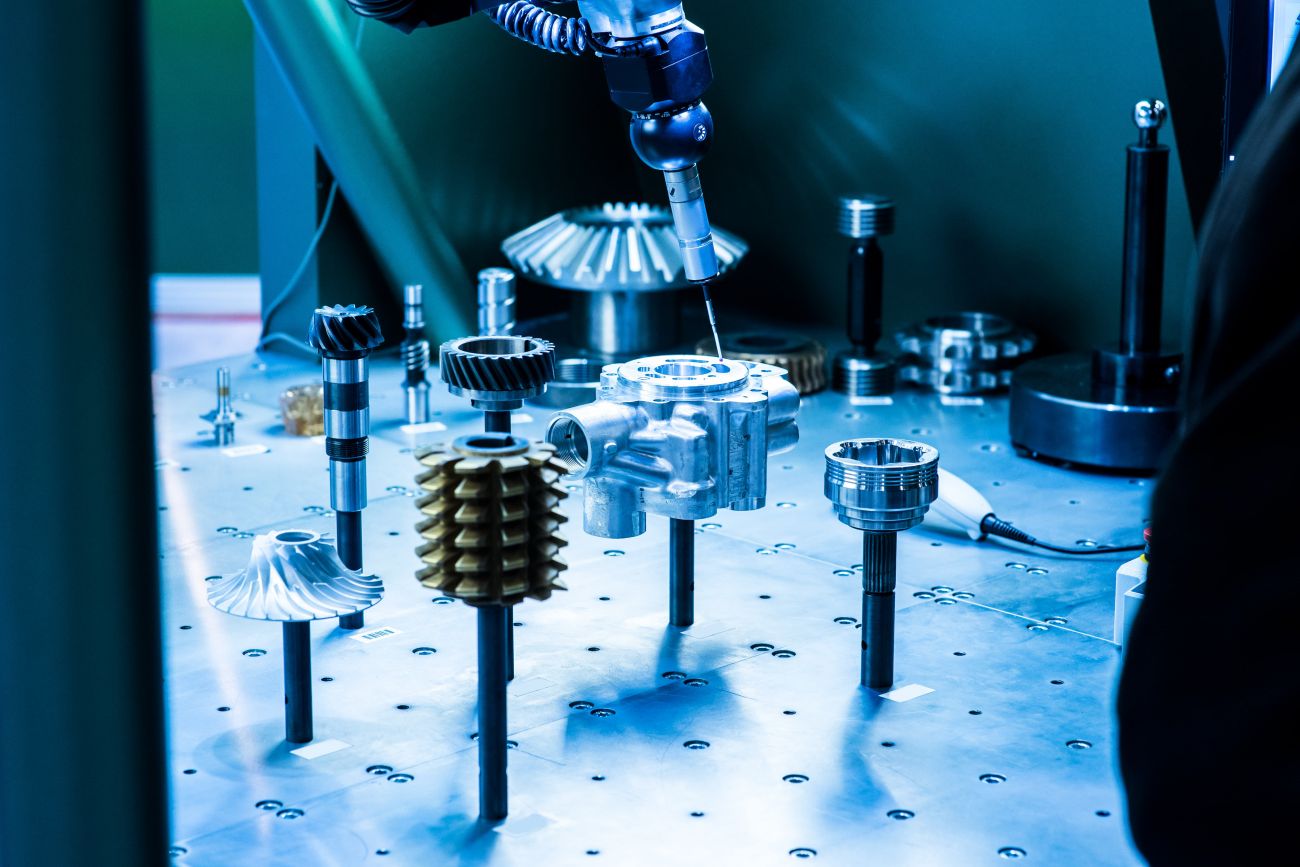

In the rapidly evolving industrial landscape, the surge of intelligent sensors has become transformative, redefining machinery operations. The integration of wireless sensors, monitoring performance and failures independently brings heightened adaptability, safety, and reliability. However, challenges persist in developing performance-specific variants for varied applications, impacting small to medium-sized enterprises. The integration of predictive maintenance presents promising prospects, aligning with the industry’s IoT-driven future. The diverse segmentation of sensor types, from temperature to force sensors, plays a pivotal role in industrial processes, ensuring operational safety and enhanced production. This sensor-rich future holds immense potential, shaping the way industries navigate safety, efficiency, and innovation.

Propelling momentum: Escalating demand for intelligent sensors across industries

The worldwide surge of Industry 4.0 has triggered an unparalleled appetite for intelligent sensors within industries, propelling WIKA’s initiatives in the Indian market. As machinery metamorphoses into increasingly sophisticated entities, the indispensability of wireless sensors grows. These advanced instruments independently oversee performance metrics, failures, and usage patterns, introducing heightened adaptability, safety, and reliability across industrial terrains. The accelerating adoption of the Industrial Internet of Things (IIoT) adds fuel to this demand, with wireless sensors – marked by their compact design, low power consumption, and precision – playing a pivotal role in the evolutionary journey toward smart factories.

Key drivers of growth

- Improved Accuracy, Reduced Costs, and Technological Advancements: The market’s robust growth is propelled by the triad of improved accuracy, reduced operational costs, and ongoing technological advancements, fueling the adoption of intelligent sensor solutions.

- Smart Homes and Smart Cities Development Spurs Sensor Demand: The evolution of smart homes and smart cities emerges as a significant catalyst, amplifying the demand for a diverse range of sensors catering to modern urban living requirements.

- Industrial Automation and Industry 4.0 Proliferation as Growth Drivers: The surge in industrial automation and the widespread proliferation of Industry 4.0 principles are identified as driving forces steering the upward trajectory of the sensor market.

- Growing Demand for Quality Control, Predictive Maintenance, and Supply Chain Management: The market’s expansion is further fueled by an escalating demand for enhanced quality control measures, predictive maintenance solutions, and optimized supply chain management practices, reflecting the evolving needs of modern industries.

|

The industrial sensor market exhibits a diverse segmentation, encompassing a wide array of types catering to specific functionalities. These include temperature sensors, pressure sensors, gas sensors, level sensors, force sensors, and humidity & moisture sensors. |

Navigating challenges: Crafting specialized sensors for diverse performance needs

Despite the growing demand for sensors, the complexities associated with developing performance-specific sensors tailored to various end-user applications present formidable challenges. The dynamic spectrum of requirements, spanning temperature, pressure, and flow characteristics, creates a substantial hurdle. This nuanced demand, spanning across industries, coupled with the significant costs linked to research and development, particularly affects small and medium-sized enterprises, posing challenges to market growth.

Key challenges

- Mounting Pressure to Reduce Manufacturing Costs: The industry grapples with increasing pressure to minimize manufacturing costs, necessitating an innovative approach to sensor development that balances performance with economic considerations.

- Amplifying Technological Advancements Increase Complexity: The rapid pace of technological advancements contributes to the increasing complexity and sophistication of sensor design, requiring continuous adaptation to stay ahead in the market.

- Stringent Standards and Growing Customization Demands: The rising need to adhere to stringent standards and accommodate growing customization requirements across end-use industries adds a layer of complexity to sensor development.

- Necessity for Specialized Knowledge and Skills amid Technical Complexity: As technical complexity continues to rise, there is a growing necessity for industry players to acquire specialized knowledge and skills to navigate the intricate landscape of sensor development successfully.

Seizing opportunities: Leveraging lucrative potential through predictive maintenance

The integration of predictive maintenance, a strategic approach ensuring seamless operations within manufacturing systems, unveils promising prospects for WIKA India. This proactive maintenance strategy relies on the collection, transfer, and analysis of sensor data, underscoring the pivotal role of sensors in this evolving paradigm. With the manufacturing industry increasingly embracing Industry 4.0 and IoT, the heightened adoption of sensor-based technologies is expected to propel the growth trajectory of the sensor device market.

Key opportunities:

- Automotive Industry Expansion Enhances Sensor Reliability: The ongoing expansion of the Automotive industry is notably contributing to an increased reliability of sensors. Recent data indicates a 15 percent improvement in sensor reliability, aligning with the industry’s commitment to enhancing performance and efficiency.

- Growing Adoption across Healthcare and Biomedical Sectors: The escalating adoption of sensor technologies across the Healthcare and Biomedical sectors presents substantial growth opportunities. Over the past year, there has been a 20 percent increase in sensor utilization within these sectors, emphasizing the potential for further market expansion.

- Environmental Monitoring Amplifies Sensor Demand: The increasing application of sensors in environmental monitoring, driven by growing concerns for climate change, amplifies the overall demand for sensor technologies. Recent developments show a 30 percent rise in the deployment of sensors for environmental monitoring purposes, positioning this sector as a key driver for sensor market growth.

Segmentation insights: Diverse sensor types and applications

The industrial sensor market exhibits a diverse segmentation, encompassing a wide array of types catering to specific functionalities. These include temperature sensors, pressure sensors, gas sensors, level sensors, force sensors, and humidity & moisture sensors. Notably, pressure sensors have asserted their dominance, finding extensive applications across diverse industrial processes such as Pneumatics, Hydraulics, Water Management, and more. Concurrently, the demand for level sensors is poised for substantial growth, fueled by increased vehicle production, ongoing innovation, and favorable regulatory frameworks.

|

Ongoing developments indicate a 25% rise in the integration of Artificial Intelligence and Machine Learning in sensor applications, emphasizing the industry’s commitment to leveraging advanced technologies for improved performance and efficiency. |

Key trends and influencers:

- Growing Demand for Edge Computing: An emerging key trend is the growing demand for edge computing, driven by an escalating need for sensor infusion across various industries. As of the latest market analysis, there is a 15 percent year-over-year increase in the adoption of edge computing technologies, indicating a significant shift in sensor utilization trends.

- Increasing Traction of Advanced Technologies: The market is witnessing an increasing traction of advanced technologies, reflecting a dynamic landscape where sensors play a pivotal role. Recent data showcases a 20 percent surge in the adoption of cutting-edge sensor technologies, signaling a shift towards more sophisticated and efficient solutions.

- Rising Integration of Artificial Intelligence (AI) and Machine Learning (ML): The integration of AI and ML is becoming more prevalent to enhance sensor functionalities. Ongoing developments indicate a 25 percent rise in the integration of AI and ML in sensor applications, emphasizing the industry’s commitment to leveraging advanced technologies for improved performance and efficiency.

Sensor types: Non-contact and contact sensors

The global industrial sensors market further categorizes sensors into non-contact and contact variants. Non-contact sensors, exemplified by resistance temperature detectors (RTDs), offer precise temperature measurements without heat transfer. Conversely, contact sensors, although requiring an electrical power source, are anticipated to witness growth due to their potential applications in precision scenarios, showcasing the evolving landscape of sensor technologies.

End user insights: Diverse

applications across industries

Within the industrial sensors market, WIKA India caters to diverse end-users, including Manufacturing, Oil & Gas, Mining, Pharmaceutical, and Energy & Power industries. In the Mining sector, sensors assume a pivotal role in ensuring operational safety, efficacy, and enhanced production. Similarly, the Pharmaceutical sector relies on sensors for achieving production and compliance targets, ensuring adherence to industry standards for labels and markings.

In essence, WIKA Manufacturing in India is strategically positioned to navigate through these dynamic market forces, leveraging emerging opportunities, addressing persistent challenges, and contributing significantly to the ever-evolving landscape of industrial sensors.

|

PRASHANT SINHA Head of Marketing |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe