MADE IN INDIA FOR THE WORLD

At the recently concluded IMTEX FORMING 2024 & Tooltech 2024, Indian Machine Tool Manufacturers’ Association (IMTMA) acknowledged four companies for their significant contribution towards bolstering India’s export prowess and showcasing the country’s capabilities on the global stage with the highly coveted ‘IMTMA Export Performance Award’. The chosen companies include IND-Sphinx Precision Ltd, ISGEC Heavy Engineering Ltd, ITL Industries Ltd, and Jyoti CNC Automation Ltd.

In a comprehensive overview of the four companies’ export strategies, product offerings, market reach, and customer support initiatives, we delve into the intricacies of India’s thriving machinery export sector.

Global perception of Indian-made machines

The perception of international buyers towards Indian-made machines has been evolving rapidly. They are garnering increased attention for their quality, reliability, and cost-effectiveness. Mihir Baxi, President, Global Sales, Jyoti CNC Automation Ltd, says, “India is now being considered globally for the reliability and technical superiority of products developed and manufactured within the country.”

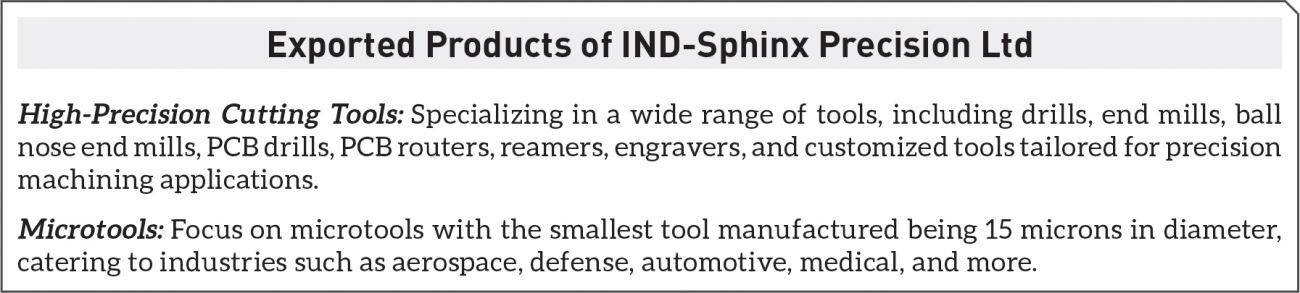

For Ronuk Taneja, Director, IND-Sphinx Precision Ltd, the outlook of international buyers towards Indian brands is changing for the better. “From being perceived as a low-cost manufacturing country, today India is looked upon as a destination for providing high-quality products at competitive prices. As an Indian manufacturer, we offer cost-effective solutions without compromising on quality, making high-standard tools attractive to buyers seeking value for money. Moreover, India is seen as a stable global partner in today’s volatile world,” he asserts.

|

According to a IMTMA report, the machine tool exports from India in the first half of FY24 was INR 716 crore (US $87 million), showing a flat rise of 2 percent. |

In alignment, Yogesh Saxena, Chief Executive, Machine Building Division, ISGEC Heavy Engineering Ltd, shares that ISGEC machines are designed and manufactured to meet international standards. He highlights, “With our unwavering focus on both customization and reliability, ISGEC empowers customers to achieve their production goals efficiently and effectively, bolstering their competitiveness in the global market.”

Taking pride in sharing the customers’ names, Saxena says that the company has a long list of loyal international customers who place repeat orders regularly. To name a few, ISGEC caters to Valeo, France; LuK, Germany; Toyota; Amvian, USA; Big Rapids, USA; Benteler, Germany, etc.

Customer-centric approach

Sharing Jyoti CNC’s long-standing experience in the international market, Baxi explains that the ‘Make in India’ Initiative, improvement in quality, ease of doing business, stable government and strong government support, technological advancement, etc. have made positive changes in the mindset of international buyers and has led to the acceptance of India as a manufacturing destination for high-tech, high-quality machines. He elaborates, “Jyoti’s products find application in various end-user industries such as Automobile, Aerospace, Allied Machinery, Die and Mold, Diamond, Defence Medical Equipment, Plastic Processing, and Textile Machinery industries.”

Saxena highlights technological advancements, customization and flexibility, strong engineering expertise, and global partnerships as additional key interest areas for international buyers. “ISGEC is at the forefront of technological innovation in the Manufacturing industry. Our commitment to advancing technology is evident through continuous research and development efforts. Our separate R&D Center is dedicated to exploring and implementing cutting-edge technologies in press solutions to address the emerging needs of the industry,” he shares. ISGEC’s pool of highly experienced engineering talent, along with renowned global chief design consultants in the press solution industry working with the company, ensures the design and production of high-quality machines. “ISGEC engages in partnerships and collaborations globally with its business associates to enhance market reach and competitiveness specific to the customer’s local market,” he adds.

|

The top three machinery types exported from April to November 2023, valued at INR 428 crore (US $52 million), were lathes (17%), vertical milling machines (15%), and horizontal machining centers (HMC) (10%). This accounted for over 43 percent of the total machine tool exports. |

Global reach

The demand for precision machinery transcends borders, with manufacturers catering to diverse markets across the globe. Taneja gives an insight into the company’s expansive reach, stating, “We export to 35 different countries, with a focus on leading technological hubs like Germany, Switzerland, Japan, and the United States. We provide precision cutting tool solutions tailored to the exacting standards of these markets. By serving these key regions, we contribute to the advancement of manufacturing technologies worldwide, establishing ourselves as a preferred supplier of high-performance machining tools on the international stage.”

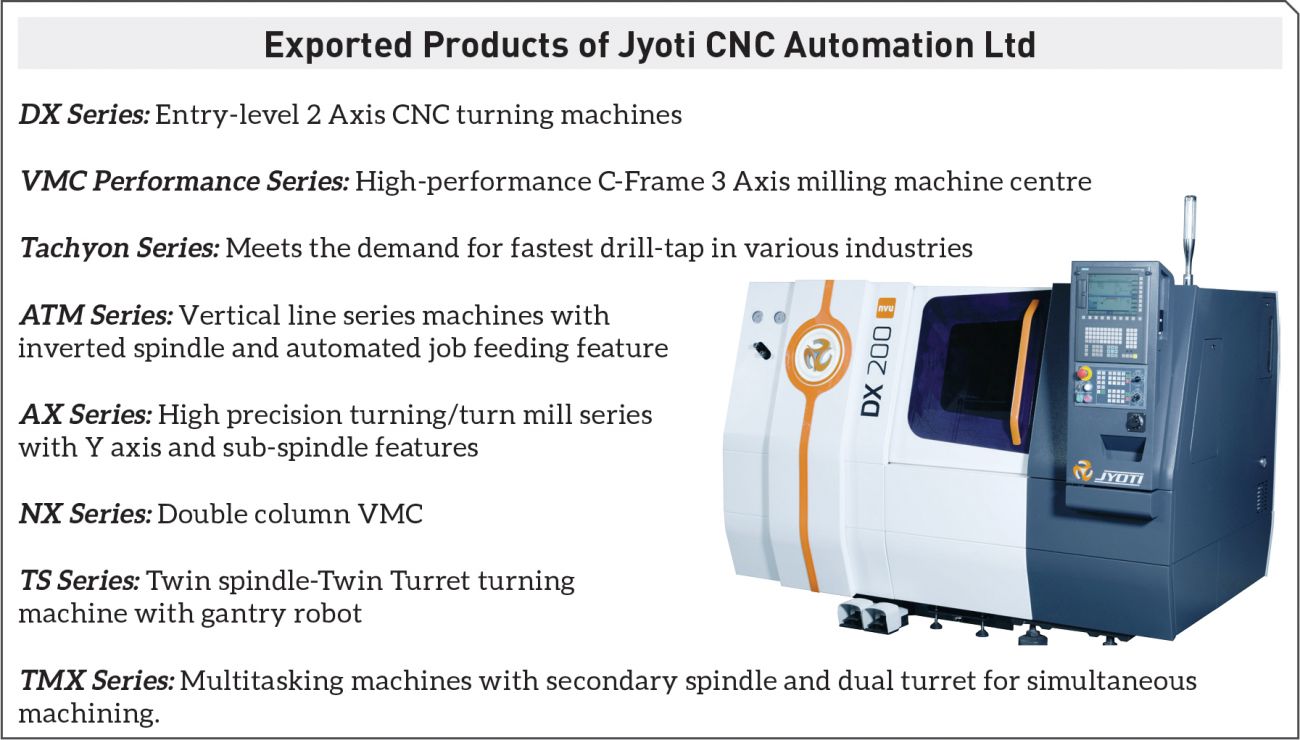

Highlighting Jyoti CNC’s widespread global presence, Baxi states, “With installations in over 60 countries like Germany, France, and many other countries across Europe, Canada, South Africa, Singapore, Mexico, Turkey, Middle East countries, Vietnam, Thailand, Indonesia, and the Philippines, we are present in the key markets with significant installation density.”

Rajendra Jain, Managing Director, ITL Industries Ltd, recollects the days when the company just stepped into exports around three decades ago. “Initially, we faced challenges, displaying our machines at international fairs like Hannover Germany and IMTS Chicago (in the years 1996, 1998, and 2000), and did not achieve much success. Our approach of selling directly to end-users wasn't effective in the global market, where distributors and dealers play a crucial role as intermediaries and are the real link.”

In 2014, a breakthrough occurred when a distributor from the USA took an interest in ITL Industries’ NC Carbide Circular Saw Machine during the Shanghai Show. Recognizing its potential, the distributor proposed to sell ITL Industries' machines through their network in North America and Europe, areas where NC Carbide Machines were not part of their product portfolio. “We agreed to the distributor’s condition of selling under his brand name, marking the beginning of our export journey in 2016. Presently, we export NC Carbide Circular Saw Machines and Band Saw Machines to North America, European Union, Russia, UK, and Australia,” informs Jain.

|

Machine tool exports during CY2023 from India reported an 8 percent growth, amounting to INR 1,543 Cr (US$ 185 M) and consumption is estimated to have increased by 13 percent to reach INR 25,283 Cr (US$ 3 B) in CY2023. |

Elaborating on ISGEC’s global footprint, Saxena says, “We export our advanced mechanical press solutions to key markets around the world like Germany, USA, Spain, Hungary, Slovakia, Poland, Czech Republic, China, South Africa, France, Brazil, Iran, Thailand, Indonesia, Vietnam, etc.”

Extending support and hand-holding

Emphasizing the importance of after-sales service and support, Jain says that though erection commissioning and after-sales service support is the responsibility of the distributor/dealer, ITL Industries trains the customers' technical teams at the company’s facilities in Indore. For special-purpose machines, ITL Industries sends its technicians to the customer’s site at its own cost. This approach ensures that customers receive prompt and effective support, wherever they are.

Outlining the company’s approach to lending technical support for its international customers, Saxena shares, “We have dedicated technical support teams equipped with extensive knowledge and expertise in our products and solutions. These teams serve as primary points of contact for international customers, offering prompt and personalized assistance to address any technical inquiries or issues.”

Additionally, ISGEC has a strong global network of service partners locally located in key regions to ensure timely and efficient support to its international customers. According to Saxena, these service partners employ skilled technicians and engineers, trained in ISGEC products, to troubleshoot and resolve technical issues quickly and effectively. They also have the necessary equipment to install the company's presses and offer prompt service to customers.

For remote technical assistance, he states, “We use modern communication technologies to provide remote technical assistance to our international customers. Through phone, email, video conferencing, and remote desktop support, our technical experts can offer real-time guidance and troubleshooting assistance to resolve technical challenges and optimize machine performance.”

“For on-site issues, we send our qualified service engineers to the customer's location to provide hands-on support and maintenance services. Our experienced service engineers along with local partners in the specific country, who are equipped with the necessary tools and equipment, address complex technical issues and ensure minimal downtime for our customers,” he mentions.

|

For exports, Russia (29%), China (9%), and the USA (9%) emerged as the top three export destinations, accounting for 47 percent of total machine tool exports from April to November 2023 with a total export value of `1,005 crore (US $121 M) and 4,515 units of machines exported. |

In sync, Baxi shares that after-sales support is highly crucial to ensuring smooth performance of the machines. The company follows the below steps to ensure support for international customers:

Local Presence – Jyoti CNC’s dealers and sole selling agents appointed in respective countries have Jyoti-trained engineers and service setups with the required spares. For any critical technical assistance, the company’s engineers from India visit the customer. For the initial commissioning of higher-end machines, Jyoti CNC deputizes its trained engineers in the majority of the cases.

Proprietary Software – Each Jyoti machine is equipped with special proprietary software developed by the company. The software ‘7th SENSE’ allows each machine to get connected to the company’s server through the Internet for remote diagnosis of the problem online.

Online Support System – Jyoti has an online support system to support customers 24x7 for remote diagnosis of their machines through trained engineers, extending all necessary help and assistance online.

through trained engineers, extending all necessary help and assistance online.

Ensuring technical and after-sales support for international customers involves several key strategies. To this, Taneja adds, “It is very important to establish a network of authorized service partners in different regions. Our distributors stock and sell our tools and provide technical support to customers. Often, the distributor’s technical staff visits the company for product-related training that equips them to support local customers.” He continues, “Our application team also visits customers along with the distributors in case there is a need for support. In Europe, we have our own subsidiary for stock, sales, and providing technical support for our products.”

Machining the future

In conclusion, as India strides forward as a global manufacturing powerhouse, the Machine Tool industry stands at the threshold of remarkable growth. Bolstered by initiatives like ‘Make in India’ and supported by advancements in quality standards and ease of doing business, Indian-made machines are gaining increased traction among international buyers.

|

SOUMI MITRA Editor-in-Chief |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe