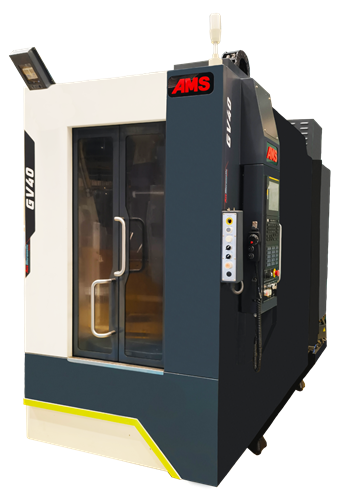

Compact VMC GV40 for Enhanced Productivity

Vertical Machining Centers

High-performance Drill Tap Center with a small footprint is always a challenge. The solution has emerged as AMS GV 40, a high-performance and high-production Drill Tap Centre. It is a compact gantry-type machine, with a high-speed, high-torque BBT-30 spindle or Direct Drive HSK A 50 spindle with 20,000 rpm as optional. The machine features a Turn Table interface with 5 sec changing time, AI servo tuning, feed-forward function, and smart spindle load control to ensure high productivity and machining accuracies.

The GV40 features a table size of 760 mm x 400 mm, with a load-carrying capacity of 400 kg. Its strokes measure at 500 mm and 400 mm. It features rapid rates of 50 m/min for each axis. Additionally, it boasts a higher spindle power, with 18.5 kW, 15 kW, and 11 kW.

Its other features include a compact design (1,280 mm in width x 3,400 mm in depth); a fully enclosed 26-tool servo-driven ATC; a coolant thru spindle; and a looping system with 4 lines per pallet.

The machine is ideally suited for a wide array of component machining applications in the Automotive, Aerospace, and General Engineering industries.

Why AMS?

AMS is the largest manufacturer of machining centers in India. The company offers a comprehensive range of products for machining components on a Drill Tap Centre (DTC). From Spark to GV40 and DTC-400XL to TCV-540, it provides solutions for machining varied sizes of components.

At PMTX 2024, the company is displaying its all-new GV 40 DTC that promises high performance and high production for a wide array of component machining applications. The focus is on maximizing the machining process, increasing flexibility, achieving smooth workflow and various types of automation.

Ace Designers Ltd – Machining Centre Division

www.acemicromatic.net

Hall & Stall: 1/ C-109

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe