FROM PROTOTYPE TO PRODUCTION

Additive Manufacturing, also known as 3D printing, has developed from its initial status as a laboratory rapid prototyping tool into an essential group of production machine tools that deliver industrial-grade end-use components. The development of 3D printing machines signifies more than innovation; it transforms how we approach manufacturing.

The Origins: Layer-by-Layer Thinking (1980s–1990s)

The concept of additive manufacturing (AM) emerged through a revolutionary notion which proposed that objects should be constructed through sequential layer additions of material.

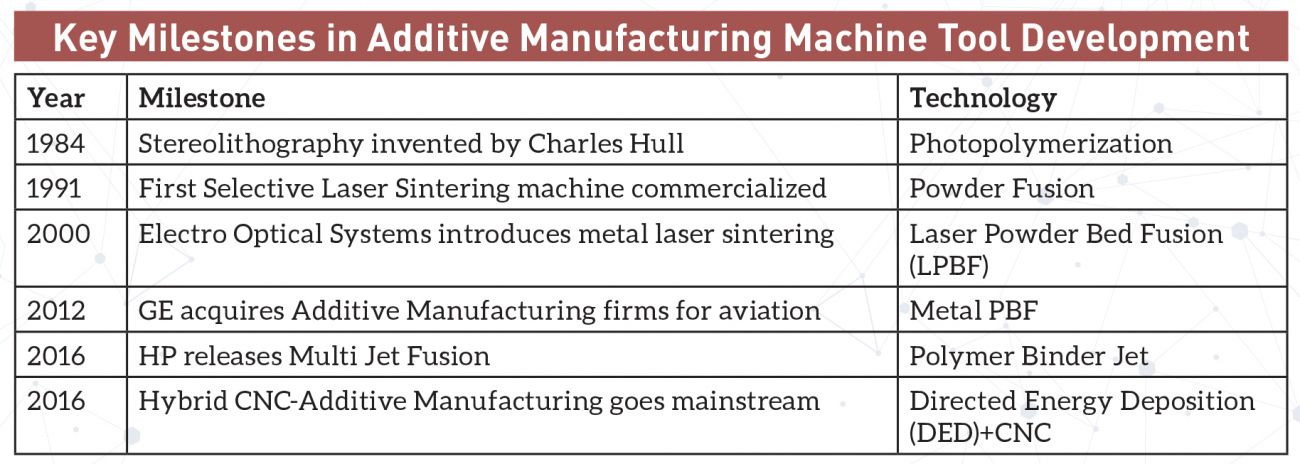

In 1984, Charles Hull developed stereolithography (SLA), the first commercial 3D printing process, which uses UV laser light to solidify photopolymer resin into three-dimensional objects through sequential layer formation.

The invention stands as the initial commercial 3D printing technology that established the principle of sequential layer construction. The photopolymer resin transforms into solid form after UV light exposure. The laser beam focuses UV energy on selected resin areas to create solidification while the process builds layers through laser-guided cross-sectional tracing.

In the early 1990s Fused Deposition Modeling (FDM) emerged as a 3D printing technology through Stratasys because it provided lower costs than other rapid prototyping systems.

The material extrusion process of Fused Deposition Modeling creates 3D objects by heating thermoplastic filament that is then extruded through a nozzle to form successive layers. FDM operates by utilizing thermoplastic filaments that come from spools that the printer uses as feedstock.

The introduction of FDM technology made 3D printing more budget-friendly than stereolithography and other early prototyping techniques. Since its introduction, FDM has become one of the most popular 3D printing technologies, finding applications in various fields like Automotive, Biomedical, and Textiles.

| The past five years have established Additive Manufacturing systems as factory-floor production machines that perform complete manufacturing tasks instead of only creating prototypes. |

Additive Manufacturing Systems Gain Factory-Worthiness

3D printing systems achieved improved precision and reproducibility through advancements in CAD, CAM, and motion control technologies, as well as closed-loop feedback, servo motors, and multi-axis control. The use of heated build chambers together with better environmental controls helped resolve problems with polymer warping and delamination. The proprietary slicer software developed better path optimization techniques which led to enhanced build reliability.

Additive Manufacturing systems gained factory-worthiness through rigorous machine design implementations from major industrial players and machine tool manufacturers.

| Additive machine tools have evolved dramatically from their initial status as laboratory curiosities into essential industrial production tools. The future of Additive Manufacturing systems will develop into factory-like machines that optimize build processes while validating quality and adapting in real-time. |

The Rise of Metal Additive Manufacturing (2010s)

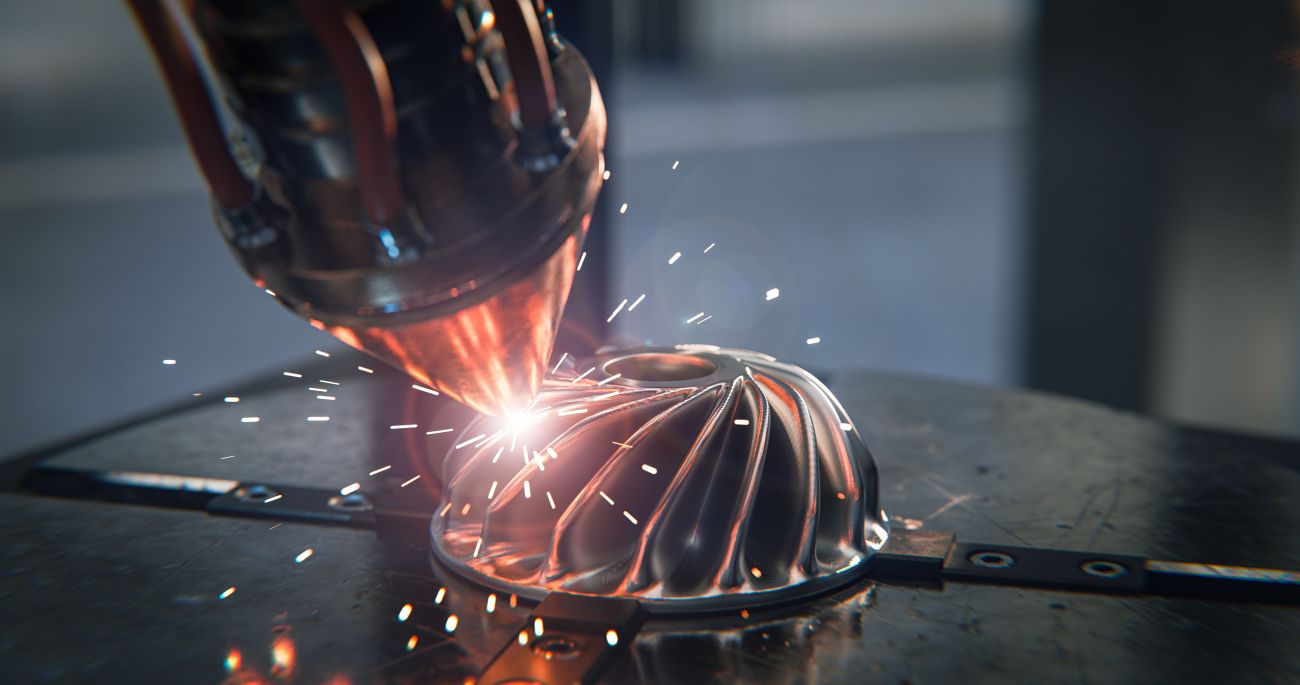

Additive Manufacturing technology experienced a fundamental transformation when Powder Bed Fusion (PBF) and Directed Energy Deposition (DED) emerged as metal manufacturing techniques.

Powder Bed Fusion

Laser Powder Bed Fusion machines took over the leading position for aerospace, dental, and medical applications. Machines progressed from using single-laser systems to adopting multi-laser high-speed scan arrays with melt-pool monitoring through closed-loop systems.

Standardization of inert gas handling systems, recoating reliability features, and real-time process analytics became mandatory.

Directed Energy Deposition

The combination of robotic arms and high-power lasers in DED technology allowed large-scale metal part repairs and hybrid Additive Manufacturing-subtractive workflows. CNC manufacturers installed DED heads onto their 5-axis machines to merge additive and subtractive manufacturing capabilities into a single platform.

3D Printing Machines Enter The Production Line (2020s)

The past five years have established Additive Manufacturing systems as factory-floor production machines that perform complete manufacturing tasks instead of only creating prototypes.

The introduction of multi-material extrusion and voxel-level control systems made it possible to produce functional gradient materials and embed electronics directly into parts. Additive Manufacturing systems gained Industry 4.0 compatibility through automated part removal functions, in-situ inspection, and integration features with manufacturing extrusion systems. Machine tool companies Mazak, TRUMPF and Hermle created hybrid machines by uniting CNC milling with metal AM that improved operational efficiency.

The process of treating Additive Manufacturing has evolved to include de-powdering, heat treatment, and CNC finishing operations, all functioning as an integrated system.

Development of Printable Materials Drives Continuous Advancements

The growth of printable materials forced corresponding advancements in machine design development. The manufacturing of PEEK and ULTEM high-temperature polymers demanded heated nozzles with vacuum beds that required enclosure temperatures to exceed 200°C. The emergence of ceramic printing techniques (slurry-based or binder jet) established new standards for powder management systems and sintering regulation methods. The evolution of bio-printing machines included the introduction of capabilities to handle soft gels and cells while maintaining sterile environments.

Each material innovation has required rethinking extrusion mechanics, thermal control, and motion accuracy.

The Future: Micro, Macro, and Multiscale

Additive Manufacturing machines are moving toward three independent yet supportive paths of advancement:

Micro-Additive Manufacturing: The combination of two-photon lithography with electrohydrodynamic jetting and nano-scale inkjet printing achieves resolution at sub-micron levels.

The technology serves applications that include microfluidics alongside photonics and biomedical scaffold development.

Large-Format Additive Manufacturing: The combination of robotic extrusion systems with wire arc additive manufacturing technology produces boat hulls, pressure vessels, and architectural structures.

Real-time monitoring of thermal distortion, together with layer alignment, represents the primary difficulty to overcome.

Multiscale, Multimaterial Systems: Printers now enable users to combine different material types in a single construction process including soft and rigid components and electronic structures and metal-polymer hybrid sections.

The 3D printing method of Volumetric printing together with computed axial lithography uses light patterns to create complete parts simultaneously.

Additive machine tools have evolved dramatically from their initial status as laboratory curiosities into essential industrial production tools. The future of Additive Manufacturing systems will develop into factory-like machines that optimize build processes while validating quality and adapting in real-time. The additive machine tool represents a digital descendant of traditional machining rather than a direct competitor to it.

| Tech Talks is a column by industry veteran and journalist Reji Varghese that talks about the latest advancements in Machine Tools, provides snippets from history, interesting facts, etc. about the Machine Tool industry. |

|

Reji Varghese |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe