BALANCING EFFICIENCY AND ENVIRONMENTAL RESPONSIBILITY

Built on the backbone of Industry 4.0 technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and digital twins, sustainable smart manufacturing offers a roadmap where operational excellence aligns with green goals.

In the face of climate urgency and increasing pressure on industries to reduce their environmental impact, manufacturers today find themselves at the crossroads of innovation and responsibility. The emergence of sustainable smart manufacturing is a compelling response to this challenge—an approach that not only drives efficiency but also embraces environmental stewardship.

Integrating AI and IoT for Energy-Efficient Production

Smart manufacturing thrives on the seamless integration of machines, data, and decision-making. At the heart of this ecosystem lie Artificial Intelligence (AI) and the Internet of Things (IoT), working together to revolutionize energy management and operational efficiency.

Modern factories are no longer in the dark about their resource consumption. Equipped with IoT sensors that capture real-time data from the shop floor and AI algorithms that analyze this data for actionable insights, manufacturers are unlocking new opportunities to optimize energy usage. From adjusting machinery operations based on load forecasts to identifying and reducing idle time, the combined power of AI and IoT is enabling efficiency gains without sacrificing productivity.

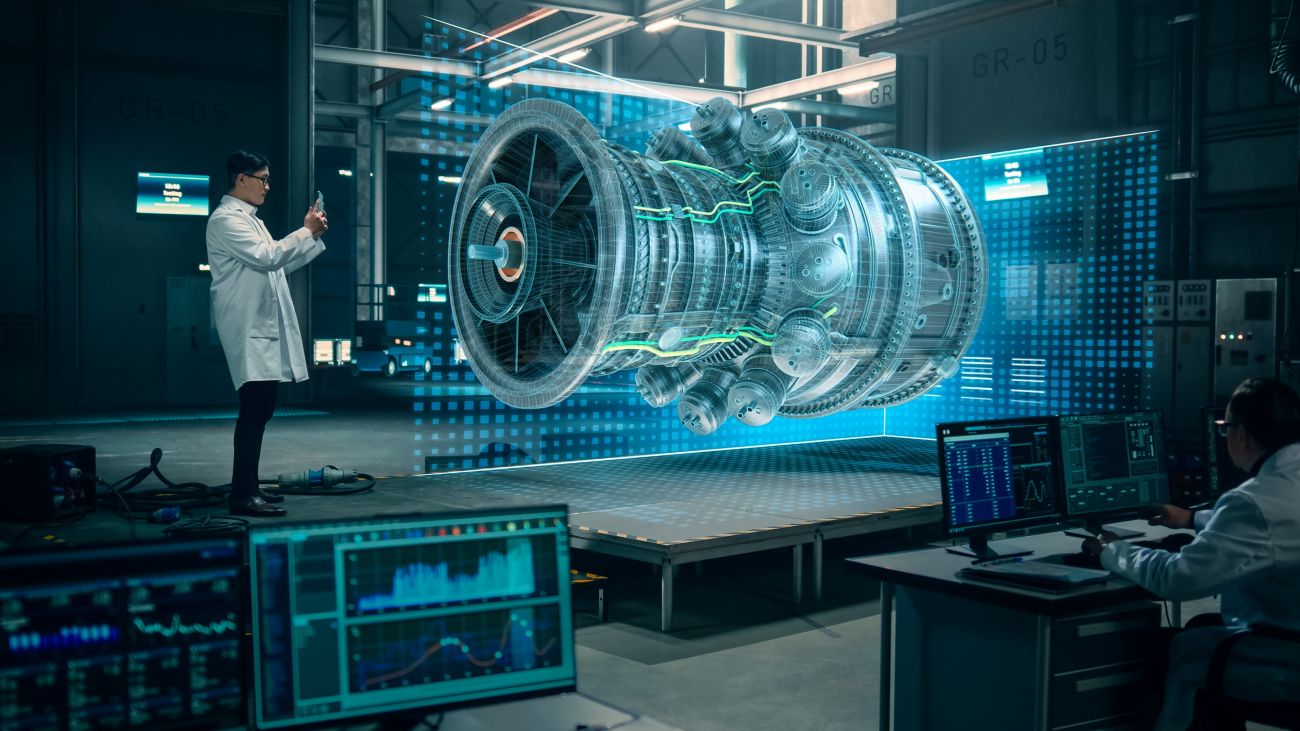

The adoption of advanced platforms such as digital twins—virtual replicas of physical systems—further strengthens operational visibility and control. In energy-intensive sectors like Battery Manufacturing, digital twin technology facilitates real-time simulation and optimization of energy flows, helping manufacturers achieve maximum output with minimal resource input.

Reducing Carbon Footprint with Smart Supply Chain Management

Sustainability isn’t confined to the factory floor; it extends across the supply chain. Optimizing raw material sourcing, transport, and logistics is crucial to lowering a company’s overall carbon footprint.

AI-driven supply chain analytics now empower manufacturers to do just that. By aligning demand with supply through rough-cut capacity planning, businesses can operate with leaner inventories, avoid overproduction, and reduce waste. Predictive models also allow manufacturers to proactively respond to supply chain disruptions, minimizing the need for energy-intensive, last-minute solutions.

In real-world applications, connected factory ecosystems allow central monitoring and optimization across multiple plants. This not only standardizes efficiency but also enhances resource sharing. In one such case, connecting over two dozen factories enabled a steel manufacturing group to reduce scrap wastage by 60 percent, significantly improving material utilization.

AI-Based Waste Reduction and Lean Manufacturing Strategies

Waste in manufacturing goes far beyond material scraps—it includes inefficiencies, unplanned downtime, and underutilized assets. AI is playing a transformative and highly practical role in addressing these challenges.

Predictive maintenance is a prime example. By analyzing machinery performance data, AI algorithms can identify early signs of potential failures, allowing manufacturers to take preventive action. This not only reduces equipment downtime but also mitigates the environmental impact associated with emergency repairs and part replacements.

AI is also enabling more sustainable product design. Advanced tools can now detect the presence of harmful or outdated materials—such as PFAS compounds—and suggest environmentally friendly alternatives. These proactive interventions support circular economy goals and ensure compliance with evolving global regulations.

| Sustainability isn’t confined to the factory floor; it extends across the supply chain. Optimizing raw material sourcing, transport, and logistics is crucial to lowering a company’s overall carbon footprint. |

Additionally, AI is reinvigorating lean manufacturing practices. With real-time data visibility, manufacturers can make agile decisions—adjusting production schedules and reallocating resources as needed. This ensures that production aligns precisely with demand, minimizing waste and maximizing efficiency.

Looking Ahead: A Human-Centric Industrial Revolution

As we reimagine the future of manufacturing, one truth stands out: the next industrial revolution must be human-centric. Sustainability, at its core, isn’t a technical goal but a societal one. It’s about creating systems that respect planetary boundaries while enhancing business resilience.

To realize this vision, it’s imperative that the private and public sectors work hand-in-hand. While manufacturers invest in future-ready infrastructure and intelligent platforms, continued policy support and regulatory clarity will be key to accelerating this transformation.

Smart manufacturing is no longer a concept of the future; it is a necessity of the present. In addition, when powered by AI, IoT, and an unwavering commitment to sustainability, it holds the promise of industries that thrive, responsibly.

|

PANDARINATH SIDDINENI |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe