WHY MODSIM IS THE FUTURE OF MANUFACTURING

With innovation cycles becoming shorter and product complexity increasing in today’s era, the old ways in manufacturing and engineering are proving to be suboptimal. By dissolving the traditional divide between modeling and simulation, embedding artificial intelligence (AI), and drawing from insights of past projects, companies are unlocking new levels of speed, accuracy, and efficiency.

A few years ago, an automotive startup found itself in a bind. They had a bold vision for an electric vehicle that could disrupt the market, but their design and engineering teams were using separate tools and working in silos. Every time the design changed—a new regulation, a new material here, a geometry tweak there—the simulation team had to start from scratch. Weeks were lost in back-and-forth adjustments, and errors crept in due to inconsistent data. Despite the team's talent, the product missed its launch window by several months, costing them both investor confidence and market momentum. This scenario, unfortunately, isn’t unique, and it underscores the urgent need for a more integrated approach to product development.

With innovation cycles becoming shorter and product complexity increasing in today’s era, the old ways of modeling and simulation in manufacturing and engineering are proving to be suboptimal. While most industries have shifted from 2D to 3D design environments, the advantages of doing so are frequently offset by disconnected processes and siloed teams. More than ever, the need to integrate modeling and simulation seamlessly on a single platform is no longer a dream but a business necessity. This is where modeling and simulation solutions powered by the strength of generative experiences come in handy.

This shift is redefining how organizations conceptualize, validate, and launch new products. By dissolving the traditional divide between modeling and simulation, embedding artificial intelligence (AI), and drawing from insights of past projects, companies are unlocking new levels of speed, accuracy, and efficiency. Yet in many organizations, product workflows still remain disjointed. Engineers model products in one software and then manually transfer data for simulation in another, resulting in data compatibility and data repair issues. This introduces time-consuming steps and opens the door to errors. This process is not only time-consuming but also prone to errors due to multiple data translations.

Simulation teams, operating independently, often receive models that require significant rework to prepare them for analysis. They may need to remodel or simplify components, losing valuable time and sometimes introducing inconsistencies. Further more, when changes occur in the design, the simulation model must be manually updated, leading to inefficiencies, delays, and miscommunication.

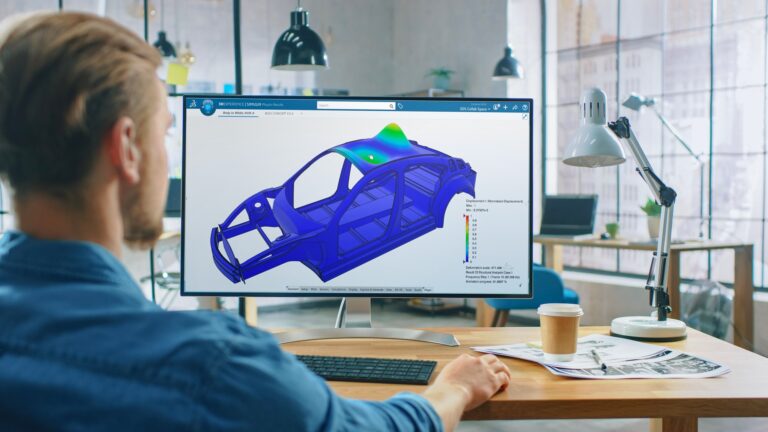

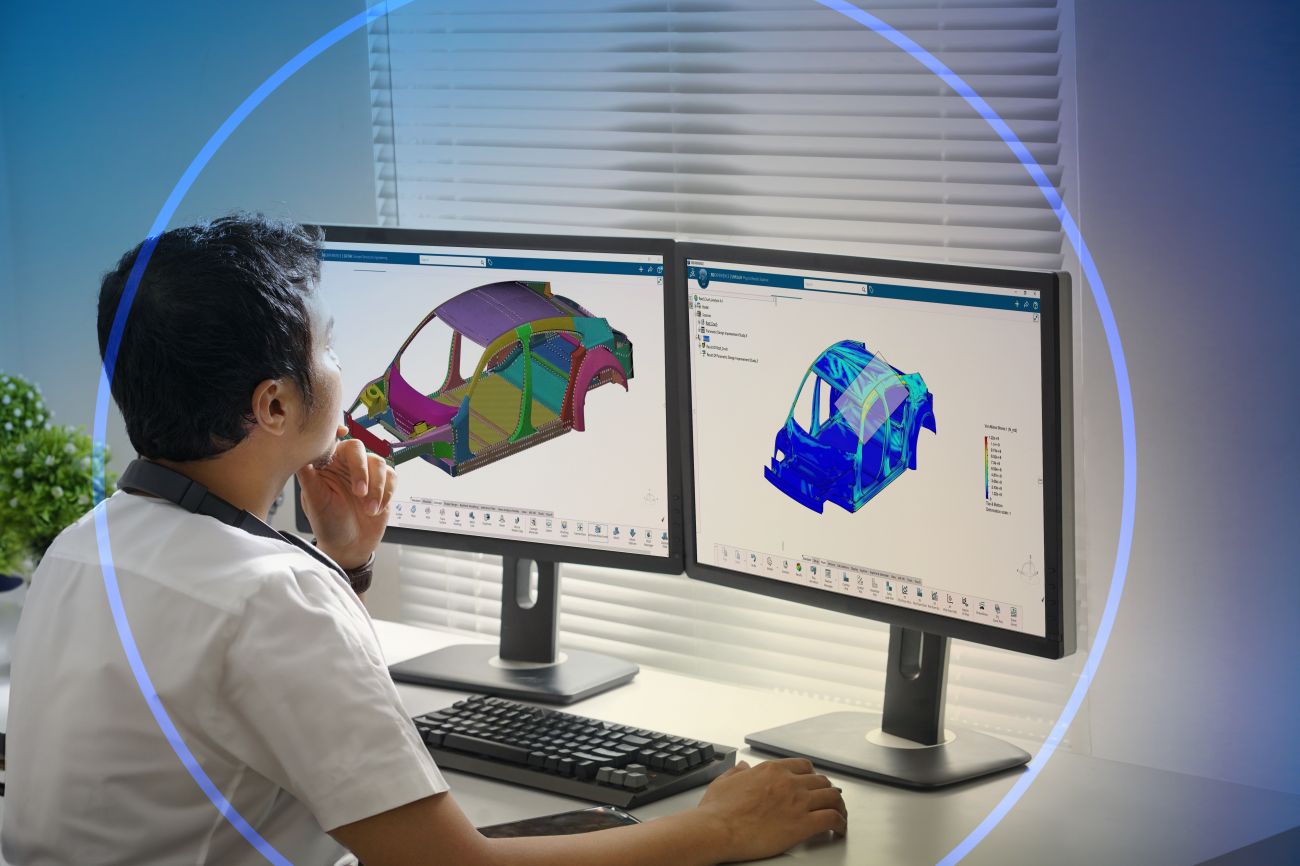

Technology brands like Dassault Systèmes address these challenges by enabling modeling and simulation to operate on the same platform and share a single data model. This revolutionary step eliminates duplication and ensures real-time associativity. Whenever a design change occurs, the simulation model automatically reflects the change. This associativity provides a huge benefit because it allows engineers to analyze the model and make confident decisions more quickly. Just think of a case where a product team is going through design iterations in real time, and every change—whether in geometry, material properties, or manufacturing method—is validated instantaneously for strength, durability, thermal performance, and any other engineering requirement. This process allows a company to reduce development timeframes from days to hours to minutes, and also improves product quality by catching potential issues earlier in the design process.

| Technology brands like Dassault Systèmes address numerous challenges by enabling modeling and simulation to operate on the same platform and share a single data model. |

The Power of Generative Experiences

While integration addresses the issue of disconnected workflows, generative experiences elevate MODSIM to an entirely new level. These experiences harness the power of AI, historical data, and simulation intelligence to offer pre-validated design recommendations. Rather than beginning from scratch, engineers can start with designs that have already been simulated under similar constraints.

Generative experiences are based on learning from the past to define the future. Through the use of large libraries of pre-validated models, businesses can speed up design iteration cycles, eliminate the repetition involved in setting up simulations, and drive performance with known solutions. This method considerably reduces time to market and enables teams to focus on creativity and innovation rather than mundane, manual tasks.

| Organizations that embrace the full spectrum of MODSIM transformation are better positioned to manage increasing product complexity and navigate volatile market demands. |

From Siloed to Seamless –

The Evolution of MODSIM

The evolution of MODSIM can be categorized into three distinct levels. The first is siloed modeling and simulation, where legacy systems operate with modeling and simulation conducted on different platforms by separate teams, resulting in fragmented workflows. The second level is integrated MODSIM, in which both disciplines converge on a single platform, leveraging a unified data model to enable seamless design-validation loops. The most advanced stage is generative MODSIM, where AI and machine learning capabilities are harnessed to generate and validate designs, simulations, and workflows.

Each step in this progression significantly enhances efficiency, collaboration, and decision-making. Organizations that embrace the full spectrum of MODSIM transformation are better positioned to manage increasing product complexity and navigate volatile market demands.

Real-World Application

A powerful public reference for MODSIM implementation is Honda, which has been using this approach for over a decade. By integrating modeling and simulation into a single environment, Honda significantly compressed its vehicle development timelines.

The firm brought out more models in a shorter duration—by almost 30 percent—achieved a competitive advantage, and enhanced market responsiveness. This was only possible by removing simulation bottlenecks, automating iterative analysis, and facilitating real-time collaboration between design and engineering teams.

While the Automobile sector leads the adoption of MODSIM, the influence of MODSIM fueled by generative experiences goes well beyond this market. In Aerospace and Defence, it facilitates simulation-based verification for safety, endurance, and mission-critical performance. In the Semiconductor industry, it aids in the design of small-footprint architectures optimized for thermal, electromagnetic, and material efficiency. The High-Tech sector benefits from its ability to manage complex electronics and embedded systems through multi-domain simulation. In Industrial Equipment, MODSIM ensures manufacturability and performance under real-world conditions. Meanwhile, in the Energy sector, it aids in designing renewable energy systems and infrastructure with a focus on resilience and sustainability.

These industries, driven by market pressures and regulatory expectations, are actively looking to compress timelines, reduce physical prototyping, and enhance product reliability. MODSIM is not just a tool but a strategy.

Reducing Time and Cost: The Bottom Line

Time and cost reduction is one of the major benefits of MODSIM and generative experiences. Organizations that implement these technologies can decrease development cycles by 30 to 50 percent, reduce prototype expenses by up to 70 percent, and improve first-right results, which minimize waste and rework costs. MODSIM also enables cross-functional teams to collaborate in parallel rather than sequentially, resulting in faster market entry, better resource utilization, and a more robust competitive edge.

Besides cost savings and cost-effectiveness, MODSIM also provides excellent compatibility with circular economy and sustainability strategies. Through simulation design before production, companies can reduce material waste, energy consumption, and greenhouse gas emissions. Generative MODSIM also supports design for disassembly, recyclability, and lifecycle extension—key circular economy principles. Companies can simulate how a product functions at each lifecycle stage, how it is repaired or refurbished, and what happens to it at end-of-life. This forward-thinking approach is essential as industries shift toward net-zero goals and sustainable development targets.

In India, companies are beginning to understand the transformative potential of MODSIM. Automotive OEMs are racing to match global development cycles, semiconductor firms are innovating under global supply constraints, and emerging EV startups are embracing digital-first strategies.

Many technology brands are actively working with Indian enterprises to implement MODSIM solutions tailored to local market needs. The demand for quicker, more cost-effective product development is not just a business challenge but a national imperative as India strengthens its position as a global manufacturing and innovation hub.

Preparing for the Future

The future of MODSIM is not just about speeding up development; it's about creating intelligence-based product ecosystems. With time, digital twins will advance further, and generative experiences will become more context-aware, allowing for real-time decision-making throughout engineering, production, and operations. NETVIBES-type tools are integral to such an evolution, enabling firms to access industry viewpoints, translate intuition into real-world results via virtual twin experiences, and leverage collective know-how for data-driven decision-making.

Firms adopting this practice will have the capacity to simulate supply chain disruptions, forecast maintenance requirements, place customer insights in design loops, and personalize products at scale with low overhead. This represents the true promise of MODSIM in the era of Industry 4.0 and digital transformation.

|

The future of MODSIM is not just about speeding up development; it's about creating intelligence-based product ecosystems. |

MODSIM is no longer just an engineering function; it is a business enabler. By collapsing the silos between modeling and simulation, and layering in the intelligence of generative experiences, MODSIM is helping companies around the world reimagine how products are designed, validated, and brought to life.

Whether one is building the next electric vehicle, aerospace component, or smart infrastructure, the future lies in adopting a unified, intelligent, and generative MODSIM strategy. The question for leaders is not ‘Should we transform?’ but ‘How fast can we get there?’

|

Praveen Mysore |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe