EMPOWERING HEALTHCARE

Backed by PLI schemes and the ‘Make in India’ initiative, Indian manufacturers are strengthening their capabilities. This presents a wide window of opportunity for the Machine Tool sector to become a reliable supplier of precision equipment to the Healthcare industry.

India is on the verge of a healthcare manufacturing revolution, ranking among the top 20 medical device markets globally and fourth in Asia, after Japan, China, and South Korea.

As the country aims for a remarkable transformation—with a bold goal of capturing around 10 percent of the global medical device market—it envisions the Indian market growing to US$ 50 billion by 2030, at a CAGR of 16.4 percent, according to the Ministry of Commerce and Industry, Government of India. Strong policy frameworks and innovation-led expansion are expected to continue driving this momentum.

A Policy Push for Progress

The Strategy Document on National Medical Devices Policy 2023, released by the Department of Pharmaceuticals, Ministry of Chemicals & Fertilizers, aims to accelerate the sector’s growth while focusing on evolving healthcare needs.

The primary objective of the policy is to build an innovative and globally competitive industry, strengthening self-reliance through automation, digital integration, and favorable policy interventions.

Recognizing its strategic importance, the Government has designated medical devices as a ‘champion sector’. The Production Linked Incentive (PLI) scheme, with an allocation of INR 3,420 crore, aims to support domestic manufacturing in critical categories such as cancer care, radiology, renal devices, and implants.

Infrastructure and Investment Initiatives

To further industrial growth, the policy allows 100 percent Foreign Direct Investment (FDI) via the automatic route for medical device manufacturing—encouraging foreign collaborations and investments.

As part of its infrastructure push, the Ministry of Chemicals and Fertilizers has launched an INR 400 crore scheme to develop world-class medical device parks. These parks—emerging in Tamil Nadu, Himachal Pradesh, Madhya Pradesh, Uttar Pradesh, Andhra Pradesh, Telangana, and Kerala—offer shared testing facilities, reduced costs, and strong logistical support.

A Turning Point

The global pandemic was a defining moment, revealing gaps in India’s medical device manufacturing ecosystem. The surge in demand for ventilators, imaging devices, PPE kits, and surgical adhesives spotlighted the urgency of local innovation and production.

At the heart of this effort was the Machine Tool industry—crucial for producing high-precision equipment across materials and applications.

The Role of the Machine Tool Industry

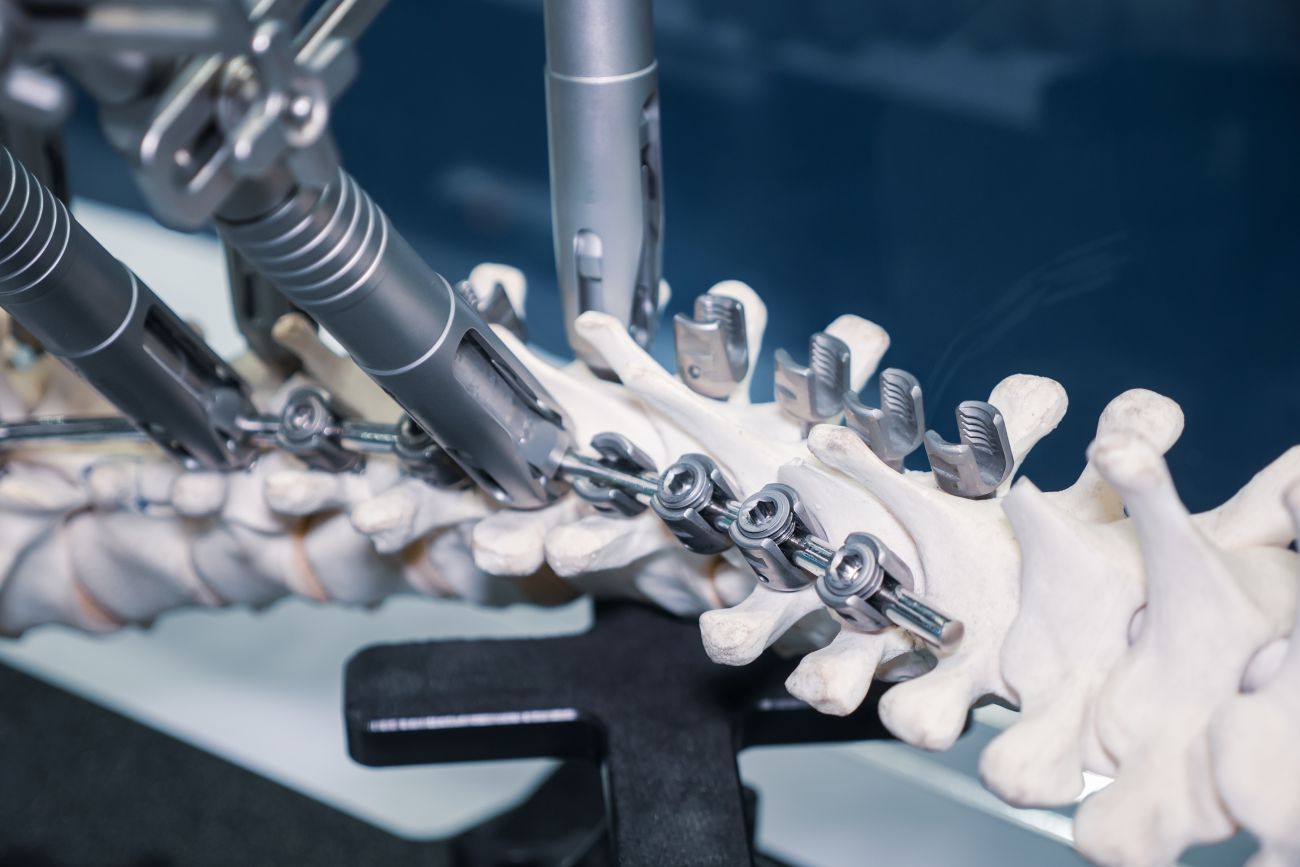

To meet the Healthcare sector’s rising needs, the Machine Tool industry must adapt quickly to deliver high-precision, multi-material manufacturing solutions. This includes machines capable of handling biocompatible and exotic materials such as titanium, polymers, and ceramics.

Manufacturers are seeking machine tools for producing various types of implants and components, such as:

Orthopaedic implants (for repairing or replacing damaged bones and joints, such as hip and knee replacements, bone plates, screws, and cartilage implants).

Cardiovascular implants (for pacemakers and implantable cardioverter defibrillators (ICDs) that monitor and regulate heart rhythm).

Neurological implants (for devices like deep brain stimulators for conditions like Parkinson's disease and spinal cord stimulators for pain management).

Dental implants (for replacing missing teeth).

Sensory implants (cochlear implants for hearing restoration and ocular implants for vision correction).

Drug delivery implants (for controlled release of medications, like insulin pumps or drug-eluting stents).

Surgical implants (meshes for hernia repair, breast implants, and tissue expanders).

Furniture (machine tools required for cutting, shaping, and finishing materials like metal, wood, and plastics).

Toward Self-Reliance

Currently, India imports a large share of high-end surgical and diagnostic devices. However, with strategic manufacturing and localization efforts, domestic production is both viable and essential.

Backed by PLI schemes and the ‘Make in India’ initiative, Indian manufacturers are strengthening their capabilities. This presents a wide window of opportunity for the Machine Tool sector to become a reliable supplier of precision equipment to the Healthcare industry.

Tech Advancements Needed

To stay ahead, the Machine Tool industry must adopt advanced technologies such as CNC machining centers (5-axis), CNC lathes, EDM machines, laser cutting/welding systems, high-precision injection molding machines, metrology and inspection tools, and other related equipment.

Additionally, investments in additive manufacturing, robotics, AI, and Industrial IoT will play a crucial role in improving traceability, quality assurance, and real-time decision-making.

| As part of its infrastructure push, the Ministry of Chemicals and Fertilizers has launched an INR 400 crore scheme to develop world-class medical device parks in several states. These parks offer shared testing facilities, reduced costs, and strong logistical support. |

Bridging Innovation and Manufacturing

Research institutions and the Medical Device Manufacturing industry need to collaborate more closely to close the gap between innovation and product development in the medical device manufacturing process, thereby accelerating the goal of self-reliance.

Trade fairs like IMTEX serve as vital platforms to showcase innovations and accelerate India's ambitions in this sector. In this symphony of progress, the Indian Machine Tool industry can play a pivotal role of enabling the medical manufacturing ecosystem to shift from import dependency to self-sufficiency, all while driving excellence and innovation in production.

Source: IMTMA

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe