Running Dry

Continuing to build its reputation for creative solutions, this multi-faceted medical device component manufacturer took its Swiss machining operations to a new level to meet a customer’s market demands.

In the fast-paced, highly regulated world of Class II and Class III medical device manufacturing, companies are often challenged by the need for a coolant-free machining environment that eliminates the potential for contamination in highly critical devices. One Minnesota-based manufacturer continues to make additional investments to ensure its customers are able to achieve critical business and manufacturing objectives, setting up individual rooms in the facility dedicated to specific customer needs. This approach has helped the company successfully meet market demand for critical, complex medical devices with a significant reduction in costs while increasing speed to market.

MMD Medical was founded in 1973, originally focusing mainly on moldmaking. Through the years, the company has expanded its capabilities to include injection molding, precision machining and assembly. Early in 2018, MMD Medical consolidated these operations into a single 100,000-sq ft facility that showcases, among other features, an almost 2,000-sq ft white room that houses Swiss machining operations that run free of cutting fluids.

Job Introduction

Job Introduction

A potential customer approached the company with an annual production requirement of 600,000 cannulas, with tight tolerances, to match a variety of surgical procedures. The cannula is a vital component of a device used in hernia repair and other abdominal surgeries. It channels air into an anatomic balloon that creates the precise amount of space inside the body to aid the doctor performing the medical procedure.

One of the tricky features of the cannula is a lumen that runs the length of the plastic tube. While that lumen is not machined (it is part of an extrusion process), its small diameter and length create challenges of contamination risk in certain machining environments, particularly those using cutting fluids—getting fluids out of the part is difficult and costly.

The previous supplier cut the extruded tubes to length before running a vertical milling process during which only one side of the tube was machined. Then the tube was manually flipped for machining of the other side. The previous production process proved inefficient and incapable of meeting the customer’s demands.

While machining without cutting fluids and using a controlled production environment with rigorous quality control processes allowed the company to eliminate risk of contamination on the device, it did not resolve all of the challenges.

A Creative Approach

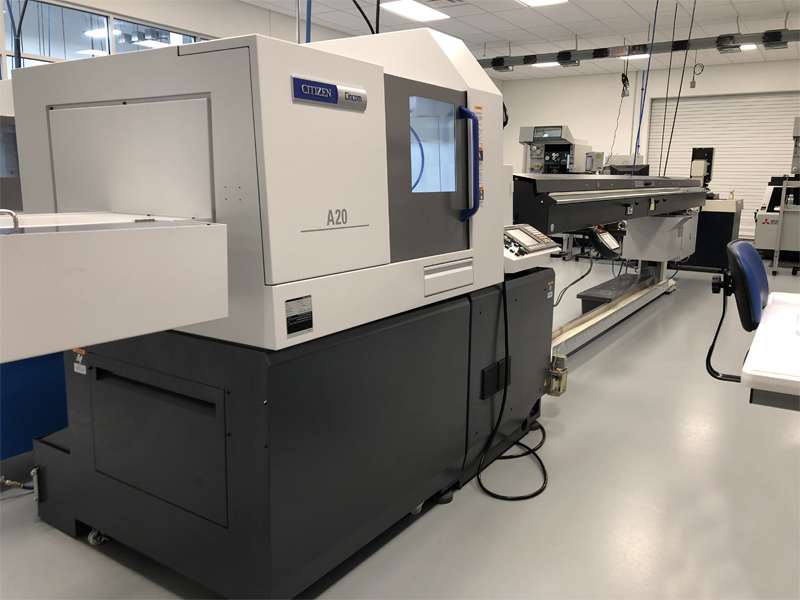

The MMD Medical team saw the chance to prove the company’s value and, hence, the opportunity to further deepen the relationship with the customer. The company was able to quickly acquire a Marubeni Citizen-Cincom A20 Swiss-type CNC automatic lathe through Productivity Inc. The company specified that all of the extruded tubes would be delivered in 12-ft lengths and equipped the A20 with a Citizen C-320 automatic magazine-style bar feeder.

“Previously, the parts were fixtured a bunch at a time, and all of the features would need to be interpolated,” says Tim Schmit, Manager, Precision Machining Operations, MMD Medical. “It was a big win for us to be able to run them automated on a Swiss-type lathe with a 12-ft bar so we wouldn’t have to cut them. They just keep producing at a high rate without the manual labor of fixturing.”

“Running a bar feeder dry is not a common practice in the industry,” says Darren Bjork, Vice President, MMD Medical. “Our team needed to do some trial and error to understand the effects of running dry to be able to develop an efficient and successful process.” Because the parts are plastic and no coolant is used, having the right tooling geometries was vital for having the heat taken away in the chip. The room where the parts are manufactured also has its own HVAC system to further separate it from areas where oils are used. While machining without cutting fluids and using a controlled production environment with rigorous quality control processes allowed the company to eliminate risk of contamination on the device, it did not resolve all of the challenges.

Overcoming other Challenges

Being plastic parts, they are highly susceptible to marring, yet as is typical in medical machining, the surface finish is critical. Avoiding scratching is difficult as the material spins at high RPM while running through an automatic bar feeder and through the headstock of a Swiss-type lathe.

Initially, as the parts moved through the bushing, they would get longitudinal scratches down the length, and whip lines would develop where the bars would rub in the bar feeder. To alleviate the problem, the company added spacers in several places, and for any component of the machine that was metal that came in contact with the part, it made replacement components out of other materials that wouldn’t mark the part. The company added a custom liner for the auto adjusting bushing and a custom spacer liner in the subspindle.

Schmit says that the most significant custom components the company built were new channel sets for the bar feeder. “Bar feeders are made to be highly lubricated, full of oil,” he says. That oil is what keeps the bar running cool and prevents scuffing.

One other adjustment came in cooperation with the machine manufacturer. To keep the machine cleaner, they minimized the oil lube to use only what is needed, rather than over-lubing, and MMD Medical maintained a protocol for wiping the machine down on regular intervals.

Favorable Result

The first production-ready cannulas were delivered in two months, which was four months ahead of schedule. Program cost was reduced by $150,000 per year, and lead times were reduced by 67 percent. The company’s willingness to invest in the right equipment and design and execute the best solution paid off in delivering for the customer. And the company has continued to strengthen the program post-launch by developing a more efficient way to apply a near-microscopic polyurethane film to each tube after machining, eliminating still more steps in the production process and further lowering costs.

Part Two

Because of its success with the cannula, MMD Medical was able to quickly secure additional work with the same customer. The next part is a component for a ligature device, a long, narrow tube that is designed to be inserted into a body during surgery to grab and tie off parts of the body via a lasso—a polypropylene suture—that is strung through the center of the device. The ligating loop is commonly used for appendectomies as well as veterinary applications.

Many of the strategies implemented on the first part carried over to this component as well. It’s a fairly simple part, but it also requires careful handling both inside and out of the machine. The material for this part also is delivered in 12-ft lengths of tube that look much like pre-cooked spaghetti. While the bars are somewhat rigid, at this length they sag considerably, so care must be taken even in racking to prevent warping of the material. The parts are also run on a Citizen Swiss machine.

On the back end of each part is a groove that is designed to allow easy breakoff of the last section, or tab, during use (once the lasso is in place). One end of the suture is attached to that tab so it can be pulled through the tube to tighten the suture. The depth of the groove is vital to allow easy, yet not premature breakoff.

One of the challenges of the part was in the original design of the groove, which was difficult to make and allow proper and consistent breakoff. MMD Medical recommended a modification to the shape, from a squared notch to a V notch, which provides a very distinct point at which it breaks. The company still runs regular break force testing of the groove, but it consistently hits within the specified parameters.

One of the challenges of the part was in the original design of the groove, which was difficult to make and allow proper and consistent breakoff. MMD Medical recommended a modification to the shape, from a squared notch to a V notch, which provides a very distinct point at which it breaks. The company still runs regular break force testing of the groove, but it consistently hits within the specified parameters.

Winning Business

The company’s business model focuses on select opportunities with key medical device manufacturers, allowing the team to provide maximum value. “We follow the 80/20 principle to allow us to focus on helping our key customers solve their biggest business challenges,” Bjork says. “Our goal is to build long-lasting relationships with major medical device manufacturers.” “Everyone is looking for cost savings,” he adds. “The advantage that we bring is that we have a team of creative problem solvers that can come up with creative solutions—and the financial strength to support the solutions by investing in the latest technology and equipment.”

The first production-ready cannulas were delivered in two months, four months ahead of schedule. Program cost was reduced by $150,000 per year, and lead times were reduced by 67 percent.

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe