OVERCOMING SUPPLY CHAIN DISRUPTION

Kirloskar Toyota Textile Machinery Pvt Ltd’s (KTTM) response to the supply chain crisis offers a masterclass in problem-solving under constraint. Rather than viewing COVID-19 disruptions as an immovable obstacle, the team leveraged lean manufacturing principles, systematic analysis, and collaborative innovation to strengthen competitiveness, reduce environmental impact, and emerge from the crisis with demonstrably superior processes.

Then the global supply chain faced unprecedented challenges during the COVID-19 pandemic, Kirloskar Toyota Textile Machinery (KTTM) found itself navigating a critical issue: container shortages and skyrocketing export costs. The team then launched an ambitious initiative to enhance container efficiency and reduce the cost burden for its customers—a project that would transform their operations and establish new benchmarks for supply chain excellence in the Textile Machinery Manufacturing sector.

The Challenge: When Demand Met Disruption

KTTM, established in 1997 as Toyota Group’s first joint venture in India, is the sole manufacturing facility producing world-class ring spinning machines. The company serves both domestic and global markets, with approximately 70 percent of its dispatches going through containerized sea routes and 30 percent via domestic trucks. The business was thriving, with export dispatches reaching unprecedented volumes.

However, the pandemic brought a stark reality. Container costs, which had historically remained around US$ 3,000 per unit in 2018-19, skyrocketed to US$ 24,000 in 2020-21—an eight-fold increase. Simultaneously, the availability of shipping containers plummeted as global logistics networks strained under the crisis. The combination led to fewer containers available at exponentially higher costs.

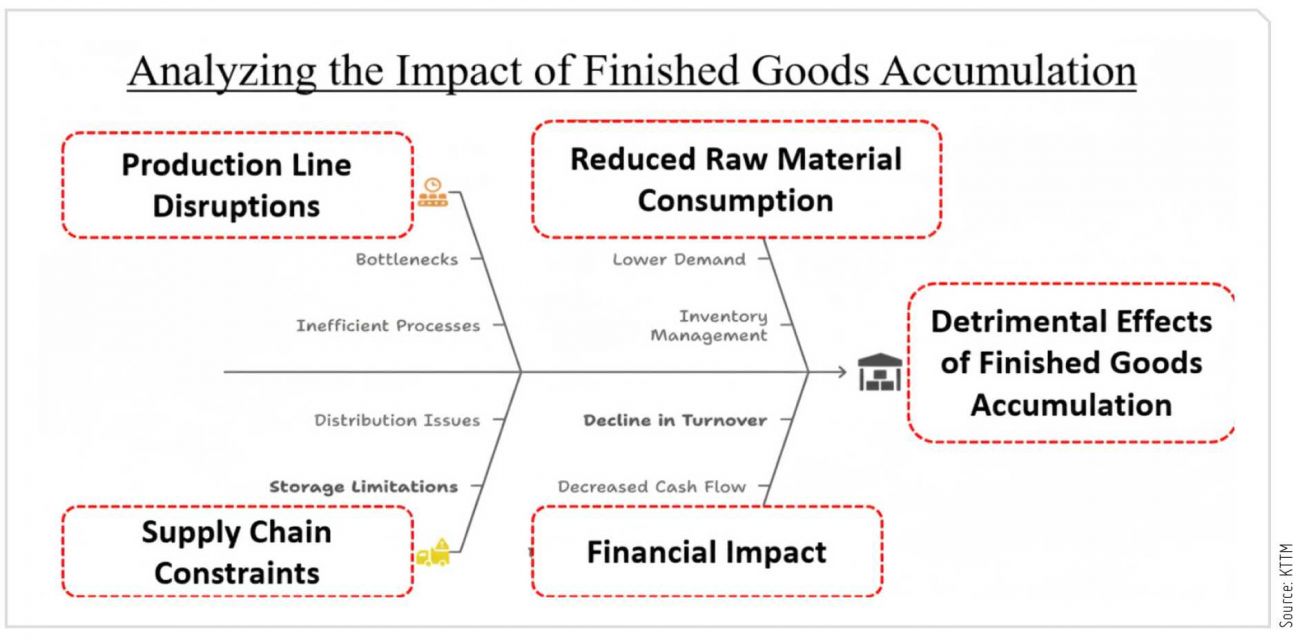

For KTTM, this meant dispatches to export customers coming to a standstill. While domestic shipments continued, the company’s 80 finished machines piled up against a storage capacity of just 20 units. Production lines faced disruptions. Raw material consumption dropped as the company grappled with inventory management. Financially, the impact was devastating as monthly inventory costs ballooned, monthly turnover crashed, and machine dispatches plummeted.

Adding to the operational nightmare, the company had to establish three separate warehouses to accommodate the backlog, incurring additional rental costs, employing additional personnel, and requiring MHEs and specialized logistics vehicles. The cost burden spiralled upward at every turn.

Root Cause Analysis: Beneath the Surface

Rather than accepting these constraints, KTTM’s cross-functional team, comprising the Operations Head, Department Heads, Section Heads, and Group Leaders, decided to investigate the fundamental problem. Using the seven quality control tools and fishbone analysis, they identified the core issue: Low volumetric efficiency of export containers.

|

When the global supply chain faced unprecedented challenges during the COVID-19 pandemic, KTTM found itself navigating a critical issue: container shortages and skyrocketing export costs. |

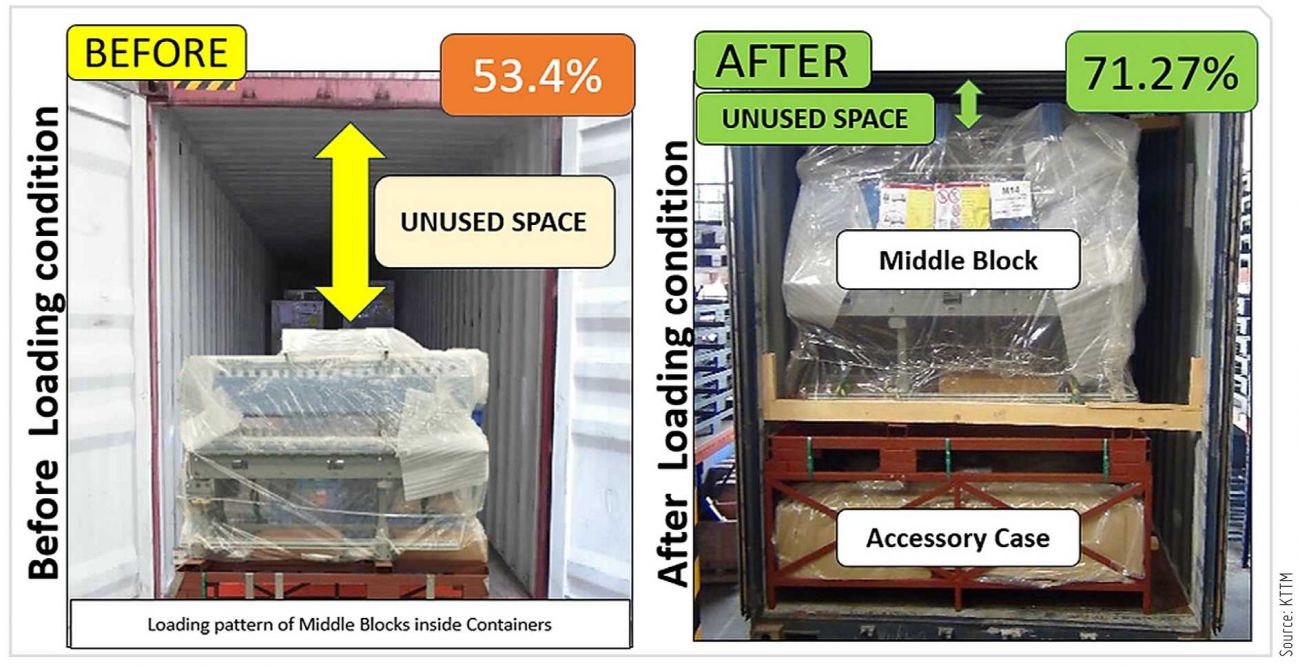

The company’s ring spinning frames were being packed in custom pallets, metal pallets for export customers, and wooden pallets for domestic customers. Each Middle Block Unit required specific handling, and due to the irregular shape of the machines’ critical parts, the blocks could not be stacked efficiently. The traditional loading pattern yielded a container volumetric efficiency of just 53 percent, meaning nearly 47 percent of valuable container space sat unused.

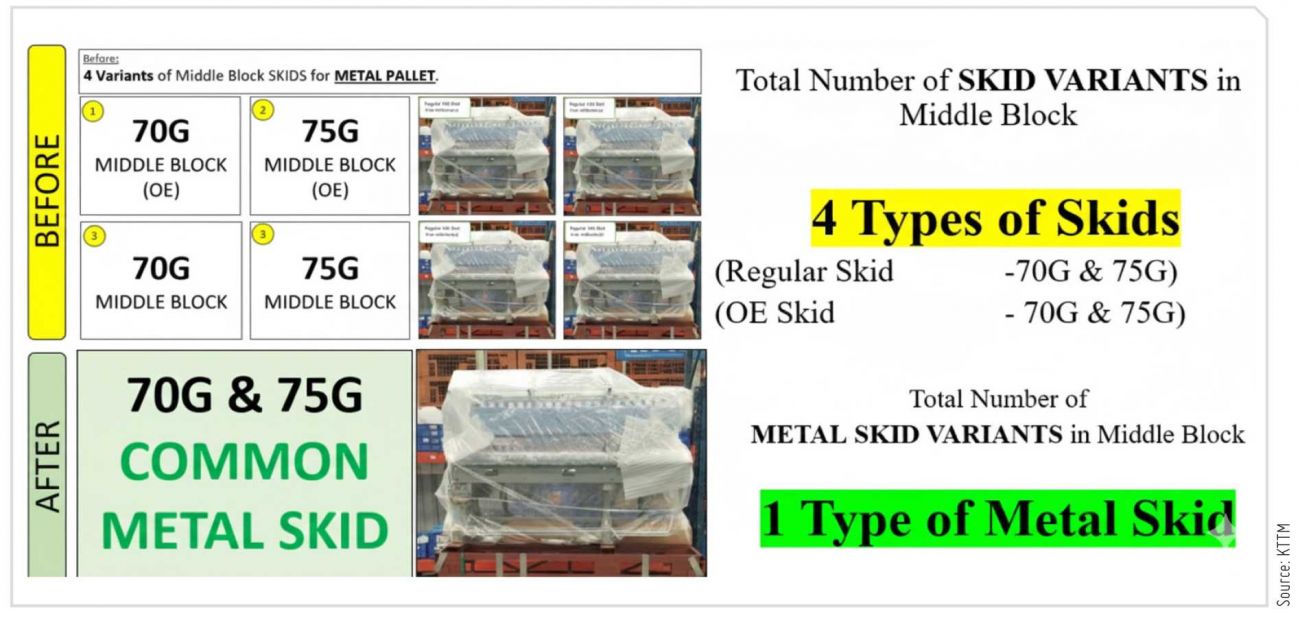

Further investigation revealed that eight different pallet variants were in use, leading to various quality issues. The company was utilizing custom wooden pallets for domestic customers and metal pallets for exports, a duplication of effort with no strategic advantage.

The Strategic Response: SEQCD Alignment

The team established clear objectives aligned with Toyota’s SEQCD principles—Safety, Environment, Quality, Cost, and Delivery. A detailed project plan was created with implementation schedules and regular follow-ups. The approach would unfold in four strategic stages.

Stage 1: Commonizing Pallet Variants (70G & 75G)

The team recognized that many pallet variants served similar purposes with minor differences. By commonizing the different variants of Middle Block pallets, the team reduced the total number of variants from 8 to 4. This simplification eliminated supplier confusion, reduced line rejections and stoppages, and streamlined production scheduling. The move toward standardization, a cornerstone of lean manufacturing, had begun.

Stage 2: Eliminating Redundant Pallet Types

Building on this success, KTTM took an aggressive step: eliminating the special pallet variants. By consolidating these functions into a single common metal pallet design, the total number of metal pallet variants dropped from 4 to 1. This dramatic reduction in complexity further enhanced supply chain reliability and reduced manufacturing costs.

Stage 3: Eliminating Wooden Pallets

Recognizing both environmental and economic imperatives, KTTM made a bold decision: eliminate wooden pallets entirely. All customers, domestic and export, would transition to a standardized metal pallet. This decision aligned with the company’s green kaizen initiative, eliminating 1.2 tonne of wood per machine and preventing 3 trees from being felled per unit produced. Annually, this translated to 20.5 tonne of CO2 reduction.

However, this transition presented a formidable challenge: the cost for domestic customers rose sharply, which became a new challenge for the team.

Stage 4: Re-engineering for Cost Recovery

Rather than accepting the cost burden as inevitable, the team launched a comprehensive re-engineering initiative:

Through detailed load analysis using design software and theoretical calculations, engineers reduced the pallet weight without compromising structural integrity or safety. This 27 percent weight reduction translated to direct cost savings while maintaining the pallet’s load-bearing capacity.

|

The team established clear objectives aligned with Toyota’s SEQCD principles—Safety, Environment, Quality, Cost, and Delivery. A detailed project plan was created with implementation schedules and regular follow-ups. |

Implementing Metal Pallet Reuse: A critical innovation emerged. Metal pallets brought back from domestic customers could be thoroughly refurbished and reused up to three times. This circular economy approach dramatically reduced the cost-per-use metric and minimized waste.

Double-Stacking Implementation: Through rigorous testing, including fall tests, road trial simulations with cameras monitoring container integrity, and customer trials with necessary approvals from parent company TICO Japan, the team proved that Accessory Cases could support double-stacked Middle Blocks within containers. This breakthrough increased volumetric efficiency significantly.

Container Loading Optimization: Using visualization software for precise loading simulations and AutoCAD for detailed planning, the team developed optimized packing patterns. The container requirement per machine dropped from 5 to 3.5 containers, a 30 percent reduction.

Tangible Results: Transformation Across All Dimensions

Container Efficiency: The container volumetric efficiency improved by 33 percent. Container requirement reduced from 5 to 3.5 per machine, eliminating 1.5 containers per shipment.

Operational Efficiency: Monthly container loading capacity doubled from 1.2 to 2.5 machines per day, dramatically reducing the backlog.

Warehouse Consolidation: By increasing export dispatch capacity, the company successfully consolidated from 3 warehouses to 1, leading to a 67 percent reduction in monthly rental costs.

Overall Cost Impact: Monthly operational costs plummeted, amounting to a 65 percent reduction in warehouse-related expenditure.

Business Metrics: The benefit of 30 percent reduction in the number of containers required flowed directly to customers, reducing their shipping cost burden and enabling KTTM to maintain its competitive market position.

Environmental Impact: The elimination of wooden pallets prevented trees from being harvested and reduced CO2 emissions by 20.5 tonne annually.

The Kaizen Spirit: Continuous Learning

Beyond the metrics, the project exemplified the true spirit of kaizen and Toyota Production System principles. Team members documented their learnings:

- Understanding standardization and pallet design for operational ease;

- Recognizing that metal fabrication and design innovations drive operational impact;

- Appreciating the power of teamwork and cross-functional collaboration;

- Discovering that technical problem-solving aligned with TPS philosophy yields sustainable success.

The team’s approach demonstrated that supply chain challenges, when analyzed systematically and addressed comprehensively, transform into opportunities for innovation and improvement.

|

In an era where supply chain resilience defines competitive advantage, the project stands as proof that systematic methodology, team empowerment, and alignment with core principles like SEQCD can convert crisis into opportunity. |

Building Resilience Through Innovation

KTTM’s response to the supply chain crisis offers a masterclass in problem-solving under constraint. Rather than viewing COVID-19 disruptions as an immovable obstacle, the team leveraged lean manufacturing principles, systematic analysis, and collaborative innovation to reimagine its operations. The result was not merely a survival strategy but a transformation to strengthen competitiveness, reduce environmental impact, and emerge from crisis with demonstrably superior processes.

In an era where supply chain resilience defines competitive advantage, the project stands as proof that systematic methodology, team empowerment, and alignment with core principles like SEQCD can convert crisis into opportunity—delivering benefits that extend far beyond the immediate business metrics to create lasting value for customers, employees, and the planet.

|

Ajay Kumar B V Assistant Manager Kirloskar Toyota Textile Machinery Pvt Ltd ajaykumarbv@kttm.toyota-industries.com |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe