WINNING INDIA’S MARITIME SECURITY WITH MATERIALS

India’s push for self-reliance in maritime systems, security, and operations is powered by indigenous innovation in advanced, defence-critical materials. By proactively understanding current challenges in protection and operational capabilities of the Navy and maritime agencies, materials science leaders such as CUMI are aligning ongoing research to usher in newer dimensions in design and performance.

India’s ports and naval bases are the lifelines of the nation, handling over 90 percent of its trade by volume. Spread across a coastline of 11,098.81 km, these ports and bases are safeguarded by the Indian Navy, Coast Guard, and other agencies responsible for maritime security. The Indian Ocean has witnessed a rise in threats, including naval warfare, unprovoked aggression, pollution of Indian waters, terrorism, smuggling, illegal fishing, and rebel attacks on trade vessels. To effectively counter and neutralize these threats while protecting the nation’s interests, naval security systems need future-ready capabilities—both on the operational and fortification fronts.

Accordingly, the Indian Navy is rapidly modernizing, expanding its fleet size as well as operational capabilities. With plans for a larger naval fleet of 200 ships and 500 aircraft by 2050, the focus has shifted decisively towards strategic preparedness. Such high-tech naval systems also require the most advanced protection in every area of operation. Whether from ballistics and blasts or fires, ships, submarines, naval helicopters, carrier vehicles, and shipyards require the latest, most robust safeguards.

Indigenously designed advanced ceramics and new-age materials are fast gaining ground as the most reliable in protecting the country’s maritime systems. Engineered to build as well as protect a future-ready naval fleet, these materials facilitate superior performance while ably fortifying the Navy’s next-gen platforms and systems.

Strategic applications of indigenous materials in naval security

New-generation materials, advanced materials and composites are being increasingly deployed for naval defence across three mission-critical areas:

Blast- and fire-resistant infrastructure for naval bases and shipyards

Protecting naval bases and shipyards is a critical priority, as these facilities are central to maritime operations, fleet maintenance, and operational readiness. Persistent risks during instances of naval warfare include the rapid spread of localized fire, leading to blasts. Also, projectiles fired during intense maritime combat can severely disrupt operations and endanger the lives of naval personnel. Lightweight blast-proof and fire-proof composites, as well as armor-piercing bulletproof composite materials, are now vital to protect particularly vulnerable areas of ships.

Blast-resistant ceramic tiles and modular CFRP panels protect command centers, armories, and fuel depots. Fireproof composites do not emit smoke and also help contain the spread of fire to vulnerable areas like the boat hull; machinery-housing compartments; Petroleum, Oils, and Lubricants (POL) stores; galleys; and submarine battery pits.

Apart from this, passive fire protection systems, such as CUMI’s Fire Master Marine Plus Fiber Systems, are being deployed in bulkheads, ship decks, engine rooms, exhaust manifolds, and cabin doors. They provide additional layers of thermal and acoustic insulation for shipboard spaces.

Wind shield and gun mounts on large naval vessels and patrol boats can be fitted with bulletproof protective covers to shield them from gunfire. This protection extends to the ship’s crew too, by minimizing the chances of the equipment exploding when hit.

These advanced materials make infrastructure far more resilient to attack and sabotage, reduce maintenance demands, and ensure naval installations have an extended service life.

|

Engineered to build as well as protect a future-ready naval fleet, indigenously designed advanced ceramics and new-age materials facilitate superior performance while ably fortifying the Navy’s next-gen platforms and systems. |

Retrofitting, and building modern warships with robust ballistic protection

Today’s warships, both new builds and existing vessels, are getting a major upgrade thanks to advanced materials. Warships such as aircraft carriers, destroyers, frigates, as well as patrol boats require robust ballistic protection. This is especially true in the case of patrol boats which India produces in relatively large numbers. Since their smaller size makes them more vulnerable to gunfire, add-on composite ceramic armor panels are particularly useful to fortify them.

Conventional materials often limit speed and endurance capability in the face of ballistic threats and fire hazards. Composite armor panels and ceramic-based protection systems are being retrofitted onto key areas to improve fire and impact resistance.

Some of these areas are:

- Interiors of engine compartments

- Hangars for aircraft

- Gun mounts

- Interior and exterior of ship hulls

Being exceptionally lightweight, they help ships achieve higher manoeuvrability, greater speed, and lower maintenance cost over time.

These solutions also serve as a robust protective barrier against ballistic threats for mission-critical equipment such as radar radomes, main armaments, and other exposed essential systems. Adhering to the stringent requirements outlined by international protection standards, such as STANAG 4569, ensures such armor can effectively protect against a multitude of threats.

For newly constructed vessels, CFRP sheets, tubes, and custom parts make warships lighter, quicker, and easily manoeuvrable. Advanced ceramics are also deployed in missile components, radomes, and radar systems, enabling superior, reliable performance in challenging marine conditions. The use of the nanomaterial graphene can potentially help minimize the radar cross section, to avoid detection by enemy vessels.

Maritime systems can also benefit significantly from Resin Film Infusion (RFI) fabrication technique. RFI helps easily fabricate large, complex, asymmetrical composite structures such as fiber-reinforced polymer (FRP) bridges and boat hulls, economically. RFI is particularly useful in the design of hull-mounted sonar domes where acoustic transparency is vital. It can also augment resistance to impact, while enhancing the strength and durability of naval vessels.

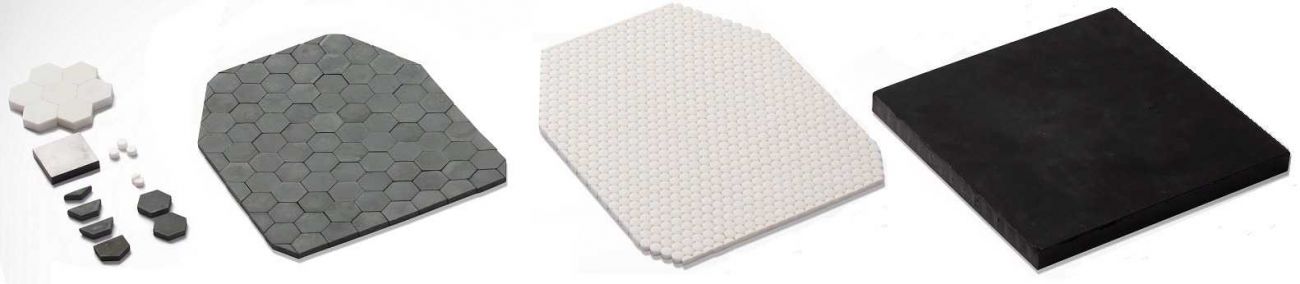

The superstructures of Anti-Submarine Warfare (ASW) corvettes, currently built with foreign Glass-Reinforced Plastic (GRP) or Fiberglass-Reinforced Plastic (FRP), can be replaced with indigenous blast-, bullet-, and fire-proof materials to boost protection and support local industry. Meanwhile, tiles developed using speciality elastomers and advanced materials are being fitted to submarine hulls to reduce acoustic signatures. Research is ongoing to improve these even further.

Lightweight armor for land and water operations

Amphibious and armored vehicles used in naval operations can be fitted with lightweight add-on armor panels made with advanced ceramics such as Reaction Bonded Silicon Carbide (RBSiC) and Zirconia Toughened Alumina (ZTA). These new solutions, qualified to meet STANAG 4569 protection standards, ensure robust ballistic protection without the added weight. The result is armored vehicles that remain highly mobile and effective across both land and naval operations.

|

Amphibious and armored vehicles used in naval operations can be fitted with lightweight add-on armor panels made with advanced ceramics such as Reaction Bonded Silicon Carbide (RBSiC) and Zirconia Toughened Alumina (ZTA). |

Composites and ceramics are also being used in underwater vehicles, as well as fast patrol boats, boosting payload, corrosion resistance, and mission endurance. These upgrades help secure coastal and island bases, ensuring operational readiness at all times.

For landing craft, research is underway to upgrade hulls and operator cabins with blast- and bullet-proof materials, providing better protection against mines and gunfire. This is particularly crucial for amphibious assaults and naval security missions.

On the cards for marine commandos are bulletproof jackets and helmets that are 10–20 percent lighter and bulletproof shields almost 50 percent lighter but with multi-hit capability. This will not only result in greater agility but also improved combat effectiveness.

Turning the tide with indigenous materials innovation

India’s push for self-reliance in maritime systems, security, and operations is powered by indigenous innovation in advanced, defence-critical materials. By proactively understanding current challenges in protection and operational capabilities of the Navy and maritime agencies, materials science leaders such as CUMI are aligning ongoing research to usher in newer dimensions in design and performance.

As we move closer to our 2047 goal, this will help to build a modern, resilient, self-sufficient maritime defence ecosystem for the custodians of our oceans.

|

Subbu Venkatachalam |

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe