MARPOSS’ BRANKAMP X-SERIES AND VARIO DUO SENSOR

Marposs offers innovative technologies for machine, tool, and process monitoring, as well as process control across all types of forming, stamping, and forging machines. These monitoring systems enable faster machine setup, improved efficiency, and higher overall productivity.

Advantages of Brankamp in the Forming Industry

The Brankamp X-series in-process monitoring systems detect overload conditions and automatically stop the machine to prevent damage and unplanned downtime. Continuous monitoring of tooling (dies and punches) in forging, fastener, and stamping applications ensures consistent performnce.

The systems detect quality defects in real time, enabling immediate corrective actions and ensuring high-quality

parts. The X-Browser and X-Client software solutions are widely used in the Forming industry, fully supporting Industry 4.0 requirements through advanced data connectivity and process monitoring.

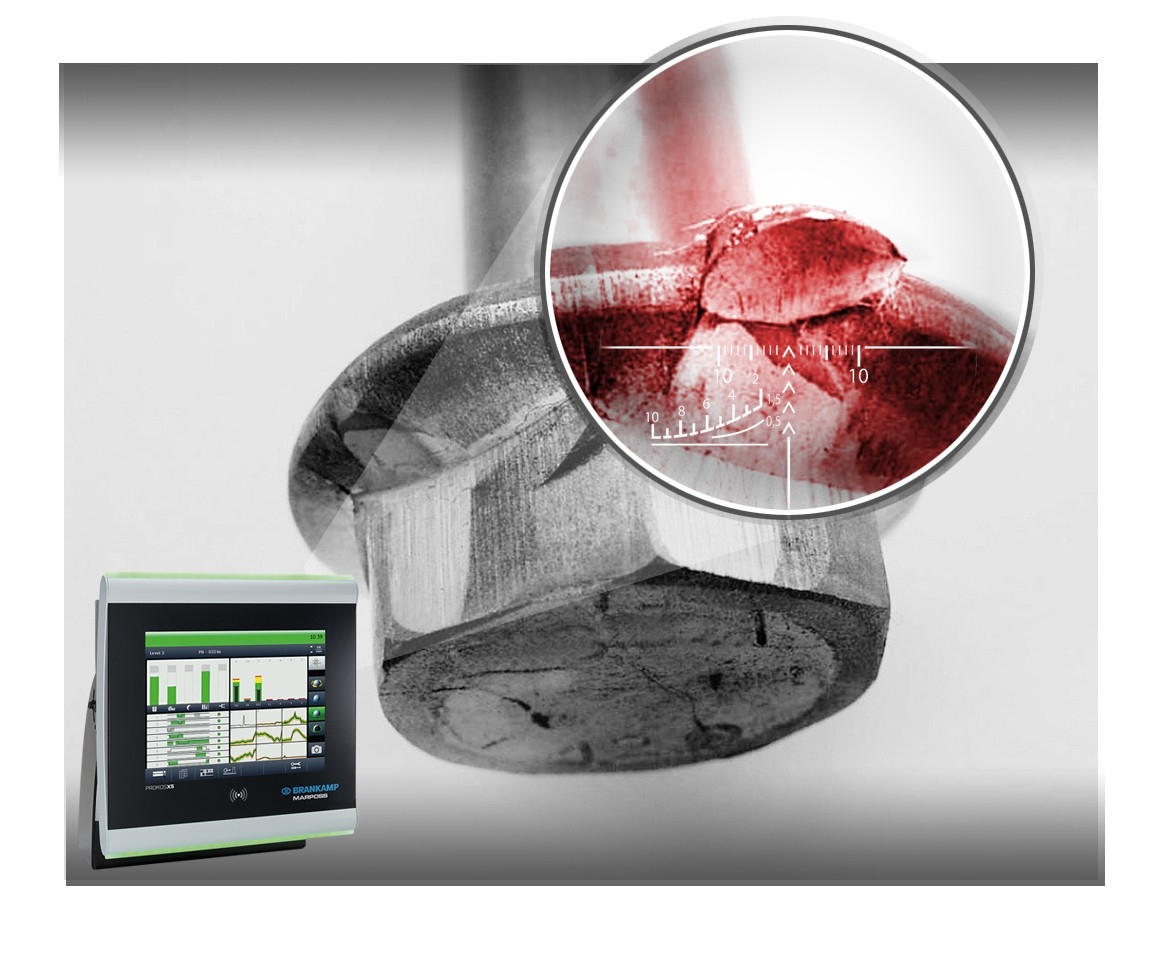

Marposs monitoring solutions detect process errors, protecting machines and tooling. Cracks on formed parts, for example, represent a typical production failure that often occurs randomly in workpieces. Such failures can only be detected through in-process monitoring of all manufactured parts.

The Brankamp X-Series high-quality in-process monitoring systems offer an effective way to observe and control the machine by detecting part defects or abnormal conditions right at the deformation stage to prevent overload or fractures in tool elements.

As soon as a significant change in the process signal occurs, the machine can be stopped to prevent expensive machine and tool damage or the defective parts can be sorted out via a sorting gate. Various sorting logics and conditions are available for this purpose.

In production processes, such as the forming of hexagon head bolts, collar bolts, or nuts, formed parts can be transferred to the next forming stage in an incorrect orientation. Characteristic ‘ears’ or scrapings occur on, for example, collar screws with hexagonal heads. These defects occur sporadically and are often not detected during manual, statistical quality inspections.

The defects can range from slight, hardly noticeable scraping to clear quality defects. The forces during part introduction into the die are very low and, therefore, represent a particularly high requirement for signal acquisition.

With the newly developed Vario Duo, this sporadically occurring ‘rotation or inserting’ problem can be detected at the existing measuring position using two sensor elements inside one standard sensor body and special software in an additional monitoring channel. The standard sensor positions prepared by the machine manufacturer can be used without additional preparation. Simple installation or easy upgrade of existing installations is possible. Well-monitored processes can run at the highest possible speed, and damaged parts are sorted out without interrupting production, resulting in increased productivity.

Source: Marposs

Facebook

Facebook.png) Twitter

Twitter Linkedin

Linkedin Subscribe

Subscribe